Analysis of structural characteristics of automatic die cutting creasing machine

With the rapid development of the packaging industry, the market demand for high performance automatic die cutting creasing machines is increasing day by day.

At present, from the existing products in the market, the automatic die cutting creasing machine products produced in China have a big gap with bobst products in terms of processing speed, machining accuracy, work stability and reliability. Product possession, improving the quality of China’s die-cutting machine products is imminent.

Automatic die cutting creasing machine structure as the core part:

The quality of its mechanical motion plays a crucial role in the overall working ability and performance of the die cutting machine. Therefore, in depth research on the working principle and kinematic characteristics of the automatic die cutting creasing machine structure is the key to improving the working ability and performance of the automatic die cutting creasing machine. The fundamental measure of product market competitiveness.

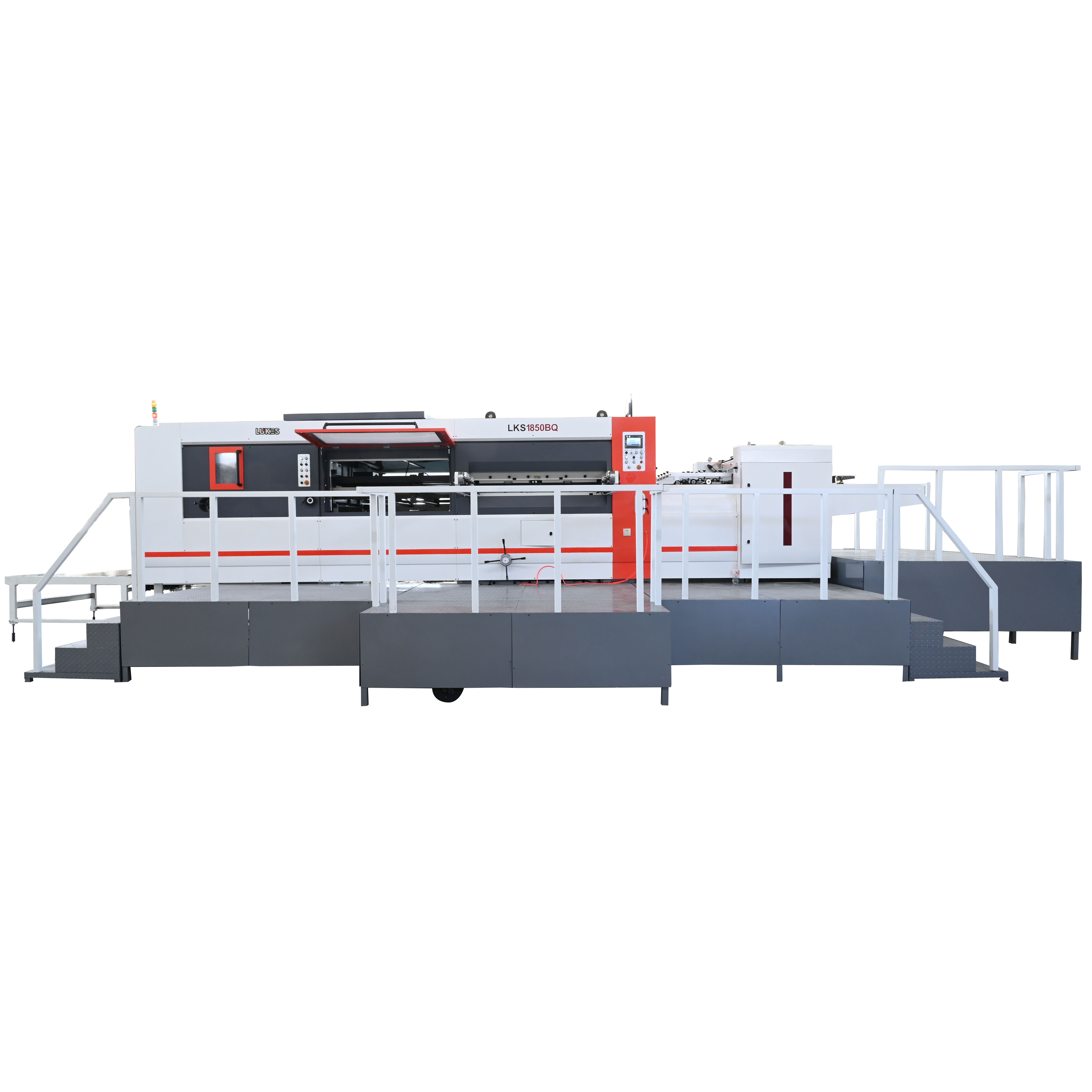

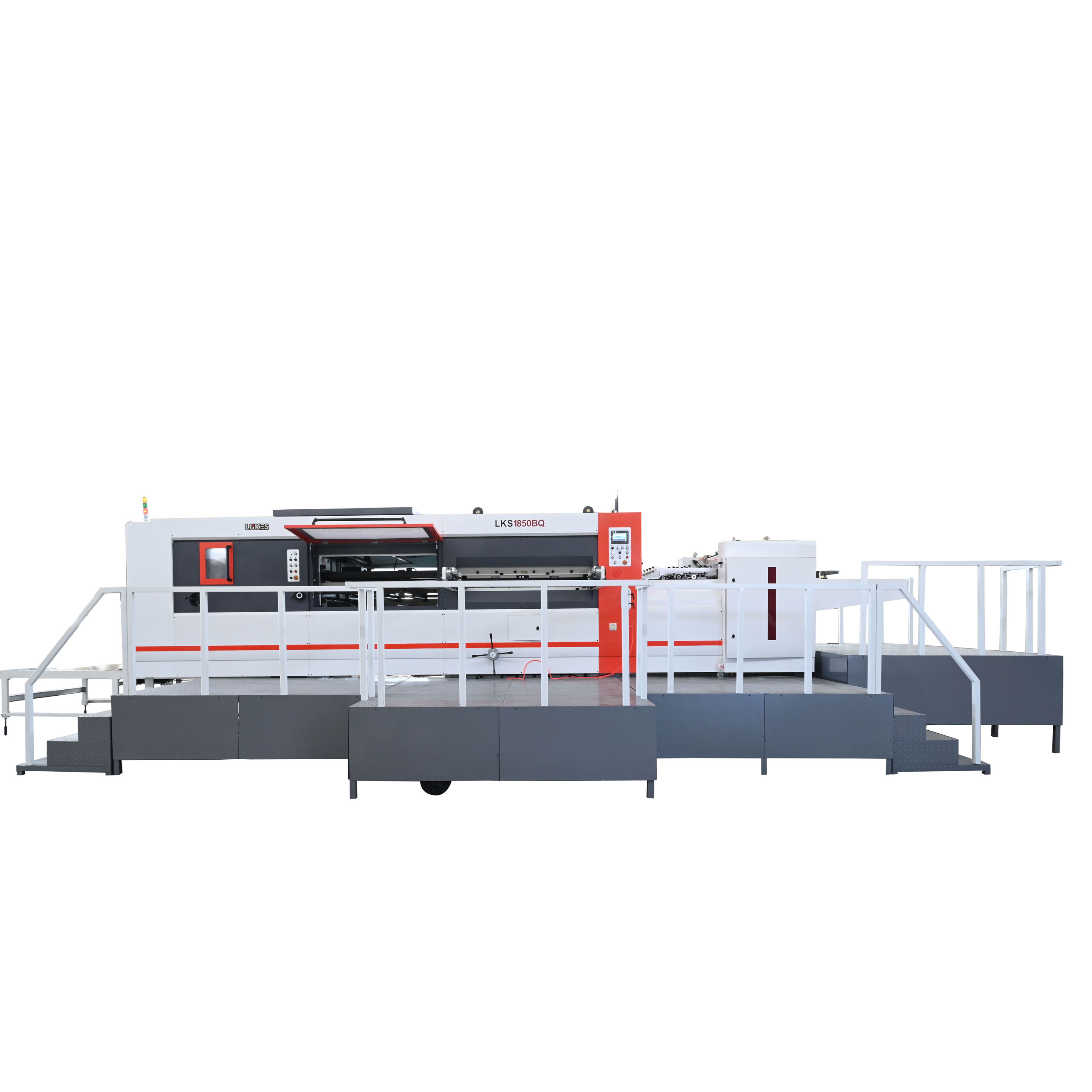

Based on automatic die cutting creasing machine products, Lukes Machinery made a systematic kinematics analysis of its double toggle lever drive mechanism, and based on the purpose of improving the kinematic characteristics of the mechanism and the quality of the die cutting process, a new conjugate cam drive mechanism was established. Mechanism design scheme, using modern design methods to carry out a comprehensive innovation and optimization design of its structure, under the premise of meeting the die cutting accuracy, the working speed of the automatic die cutting creasing machine is increased to 7500 rpm, and the die-cutting machine is increased accordingly. the overall performance of the machine.

The main work contents and research results are as follows:

Firstly, according to the existing automatic die cutting creasing machine products, a mathematical model of the die cutting mechanism is established, and the motion of the die cutting mechanism is accurately solved by using the complex vector method. The program obtains the displacement, velocity and acceleration change curves of each rod of the mechanism when the die cutting machine is at the highest working speed (7500 rpm).

According to the kinematic characteristic curve of the double toggle lever mechanism, the main factors affecting the performance of the die cutting mechanism and their influence methods are obtained:

Among them, the acceleration motion law of the die cutting platform, connecting rod and upper toggle has the greatest impact on the performance of the die cutting machine. Their peak acceleration during the movement process produces a large impact load, and the motion law of the die cutting platform is not consistent. Meet the die cutting process requirements.

Based on the purpose of improving the kinematic characteristics of the die cutting mechanism and the quality of the die cutting process, and taking the improved acceleration motion law of the die cutting platform as the design criterion, the structure of the double toggle lever mechanism is fully optimized. Instead of the crank driven design scheme, the exact reverse design of the conjugate cam mechanism is carried out through MATLAB, and the exact contour of the conjugate cam is obtained. Finally, the motion simulation analysis of the optimally designed conjugate cam drive mechanism is carried out through ADAMS, and the displacement, velocity and acceleration curve of each component in the new mechanism are obtained. The motion characteristics at 7500 rpm) are more conducive to improving the motion accuracy of the mechanism, more in line with the die cutting process requirements, making the structure simpler and more compact, and thus more effectively improving the working ability and performance of the automatic die cutting creasing machine.

Lukes Machinery is one of the well known die cutting machine brands in China. It mainly produces automatic die cutting machine, semi automatic die cutting machine and manual die cutting machine.

With professional technical research and development personnel and after sales service teams, customers are currently located in dozens of countries around the world.

If you are interested in automatic die cutting creasing machine, please send an email to [email protected].