Precautions for daily operation of carton nailing machine

Lukes Machinery is here to talk with you today about the characteristics of the carton nailing machine in the work and the problems that need attention:

First of all, we need to understand the needs of customers and get the corresponding cardboard according to the production notice.

Need to pay attention to the name, specification, model, layout and other contents of the cardboard, and also need to conduct a sampling inspection of the cardboard.

For example, cardboard size, die cutting or crimping size and method, cardboard color difference, printing color difference, warping, damage, etc.

If the quantity is large and the problem is serious, report to the process team leader in time and deal with it accordingly;

After verifying that it is correct, transport the cardboard to the machine and place it neatly on the wooden rack. At this time, pay attention to the stacking height and stacking stability.

Prepare flat wire: 10 minutes before the carton nailing machine works, pick up the corresponding flat wire according to the label, quantity, and coating of the flat wire. The flat yarns to be used are neatly placed in the specified area, and the number of requisitions shall not exceed the dedicated area.

The process team leader and the team leader can each take a cardboard box and conduct the first inspection of the product respectively. When checking, place the cardboard box under natural light.

The main items to be noted are as follows:

The nails should be fastened and ordered thoroughly, and there should be no overlapped nails, missing nails, warped nails, broken nails, bent nails, no corners, etc.

In the process of nailing the box, you should also pay attention to whether there are serious problems in the printing and slotting of the carton and whether the nailed carton is qualified!

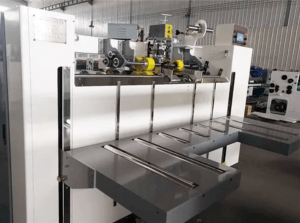

Lukes Machinery has been founded for nearly 20 years, and its main equipment includes: die-cutting machine, folder-gluing machine, stitching machine, etc.

If you are interested in our products, welcome to contact me.