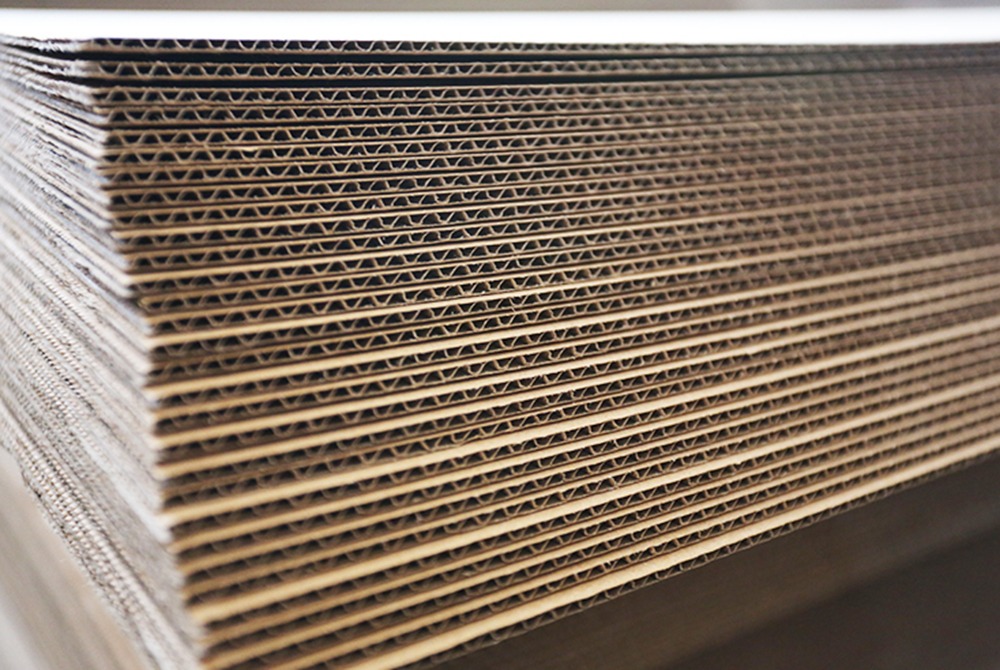

How to prevent corrugated cardboard box from bursting in winter?

[Winter Tips] To do these points in winter, the carton printing machine will not be afraid of the corrugated cardboard box breaking line during the pressing process!

Corrugated cardboard is easy to soften in rainy days, and it is easy to burst in winter. The big problem of cardboard burst is that the moisture of the paper is too low, and the carton printer will burst during the press line.

Then it’s winter, Lukes Machinery teaches you how to prevent it. There are roughly three reasons that affect the cardboard burst line:

1. Corrugated cardboard box moisture is too low

When the cardboard comes out in winter, the moisture measurement should be reasonable, but after a period of storage, the moisture of the cardboard begins to decrease. The longer the storage time, the lower the moisture of the cardboard. To ensure the moisture content of the cardboard, prevent the moisture loss of the cardboard.

(1. Reduce the cardboard storage time and control the production of cardboard within 4-8 hours…

(2. To control the temperature of the carton production workshop, you can install a spray device, add heat to the floor of the workshop and turn on the spray device when you get off work at night, so that the workshop can ensure a certain temperature. The moisture content of the cardboard will also be relatively increased.

2. Crimping wheel problem

(1. Sometimes the design of the carton machinery equipment crimping wheel is unreasonable. Generally, the factory should be equipped with 2 sets of crimping wheels, one is the crimping and pre-pressing wheel used in winter

(2. When adjusting the pressure wheel, be sure to check whether the gap of the pre-pressure wheel is reasonable

(3. For chain machines without pre-compression wheels, pre-compression wheels can be installed on the paper wheels

3. Unreasonable paper distribution

1. When the weight of the center paper is too high and the facial paper is heavier than you, then the carton is prone to bursting of the facial paper.

2. When the center paper is used in grammage, the surface paper is low, and the corrugated paper has high strength, it will also cause the inner paper to burst.

There is a lot of attention to the corrugated cardboard box, so I won’t mention it here, and it can be adjusted appropriately according to the actual cost.

When the moisture of the corrugated cardboard box is already very dry but it is about to be produced, Lukes Machinery recommends the following methods:

(1. Steam the corrugated cardboard box.

(2. Wipe the corrugated cardboard box.

(3. Install a spray device on the carton separator of the carton machinery and equipment to spray to increase the moisture of the cardboard.

(4. Use carton factory equipment paper separator to pre-press or press line.

Lukes Machinery has been founded for nearly 20 years and has a professional technical and service team. If you are interested in paper packaging machinery and equipment, please contact us.