How to extend the life of Box stitching machine?

Carton factories often complain that during the operation of the box stitching machine,

Flat wire is prone to quality defects such as cracks, rust spots, peeling, and bending.

In fact, as long as these three steps are done well, the problem can be avoided.

1. Choosing copper-plated flat wire can increase the life of the equipment

The quality of flat yarn mainly depends on the properties of raw materials and production processes.

If the flat wire is unqualified, quality failures such as coating shedding, unsmooth wire feeding, broken nails, and poor nail saw molding specifications will easily occur during use.

The annealing degree of the iron flat wire is about 400 degrees and the time is only 4 hours, while the annealing temperature of the copper-plated flat wire is about 900 degrees and the time is 14 hours. Its hardness is about 2 times smaller than the former, so it can be used. Better reduce the wear of the head components.

Therefore, from the perspective of improving the life of the equipment, the choice of copper-plated flat wire is of certain significance.

2. Purchasing flexible flat wires can reduce cracks

There are generally two types of coatings on the surface of flat wires: copper plating and zinc plating. From the perspective of quality and technology, flat wires are not allowed to have quality defects such as cracks, rust spots, peeling, bending, or uneven thickness.

Therefore, when purchasing, pay attention to choosing flat wires with good coating, good rigidity and elasticity. The uniformity of thickness and width can be tested with vernier calipers.

3. The storage warehouse is dry and ventilated to avoid rust

The wire material of the flat wire is iron wire. Although the surface has a certain anti-oxidation and anti-rust coating, it is easy to rust if it is not stored properly.

Therefore, the unused flat wire after opening the box should be stored in a sealed and moisture-proof manner.

To

Pay attention to these three points in the production process of the carton nail box equipment, which can greatly extend the life of the box stitching machine and free you from cracks, rust, and peeling of flat wires.

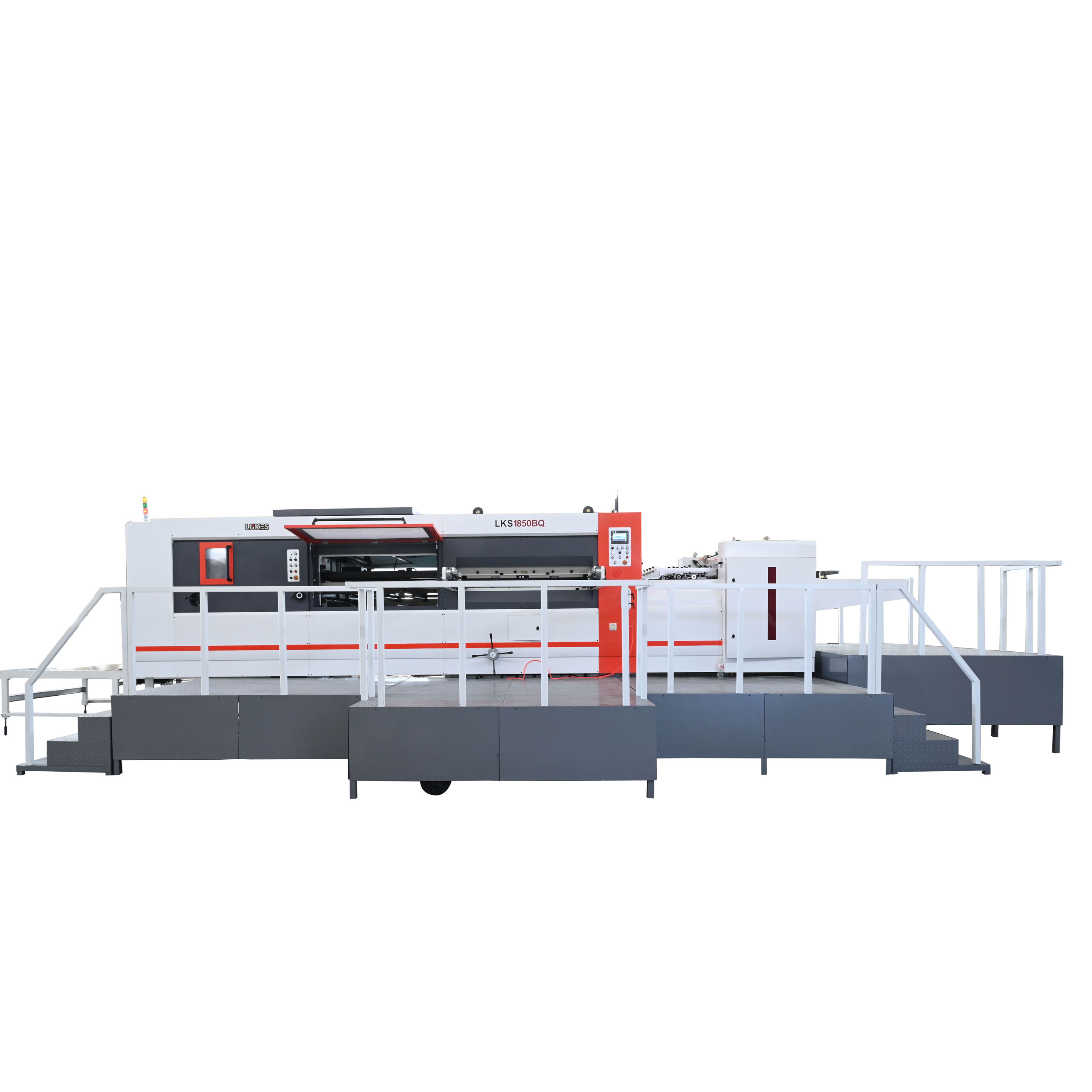

If you are interested in Die Cutting Creasing Machine and other equipment, please send an email to: [email protected]