The carton has burst lines, how to adjust the creasing matrix?

Reason for bursting line: ” bursting line” is due to the excessive pressure of die cutting and creasing, which exceeds the limit of the bearing capacity of the paper fiber, and the paper fiber is broken or partially broken;

In addition, there is another situation, that is, when die cutting a small box of hard cigarette packets, because the distance between the creasing lines in many positions is very close, if the height of the creasing steel lines is configured according to the normal situation, the die cutting will cause too much tension on the paper. It will also cause bursts. Therefore, you should try to minimize the pulling force on the paper, there are two methods:

1. Reduce the height of the creasing line;

2. is to reduce the thickness of the creasing matrix.

However, the two cannot be used at the same time, otherwise it will not achieve a good creasing effect. A better method is to reduce the height of the creasing steel wire, and the reduced height is usually 0.1-0.2mm. The reduction of 0.20mm above /m2, and the reduction of 0.10mm below 350g/m2. Same as scrub products.

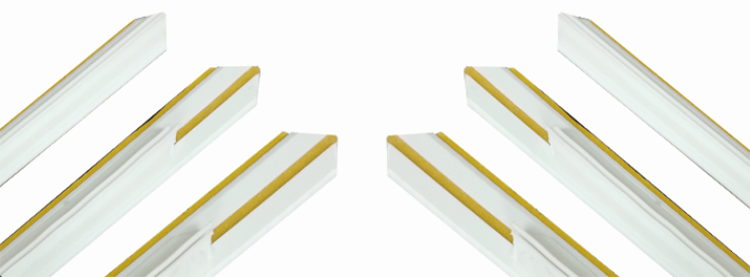

The creasing matrix is a commonly used consumable in die cutting and creasing operations. Correct selection of indentation strips of suitable size can greatly improve the quality of carton products.