Common Corrugated Box Die Cutting Machine design problems in the market

There are various types of Corrugated Box Die Cutting Machine equipment. If the waste removal equipment is not good, it will have a direct impact on the production quality and efficiency of the carton die cutting machine.

To remove waste and clean, not only need to pay attention to the mold quality and operation technology, but also how to design it.

To

Lukes Machinery gives you a small example:

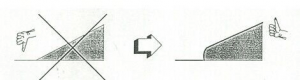

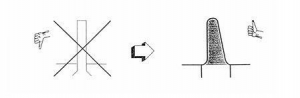

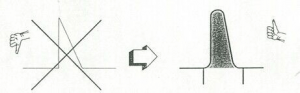

The above three pictures are the mistakes that Corrugated Box Die Cutting Machine often makes when making die cutting.

Making the die-cut notch a right angle or 45 degrees will be very poor.

Disadvantages of right angle or 45 degrees:

1. The die-cut notch is right-angled, this right-angled paper is not easy to cut;

2. When the die-cutting knife is made, joint points will appear, and the paper will not be smooth if a knife cannot finish cutting;

3. The cut edges are easy to get stuck at the included corners and not easy to fall off;

4. The notch of the mold is easy to jam, resulting in poor cleaning and deformation of the knife.

The advantages of the mold notch being round:

1. It is easy to cut the paper;

2. Finished with a knife, and the cardboard is cut smoothly;

3. The corners are not easy to jam, and the paper scraps are easy to fall;

4. The notch of the mold is not easy to jam, and the knife is not easy to deform.

Corrugated Box Die Cutting Machine If there is a problem in the operation design of the mold, it will be more difficult to strip the cartons. As long as a little change, the stripping can achieve the highest quality effect.

If you want to know more about paper processing equipment, please log in: www.sdlukes.com or contact [email protected]