Analysis of factors affecting the performance of corrugated boxes die cutting machine

There are many factors that affect the die cutting speed and accuracy of corrugated boxes die cutting machine. In order to improve the die cutting speed and accuracy and the stability and reliability of corrugated boxes die cutting machine, in addition to optimizing the design of the mechanism of each component and accurately processing each component, In addition to the rational selection of the materials of each component, the ideal assembly accuracy is also crucial to improving the stability and reliability of the whole machine. Lukes Machinery mainly analyzes how to improve die cutting accuracy and die cutting speed by the following seven analysis:

Factors affecting the processing quality and assembly accuracy of each component of corrugated boxes die cutting machine

Judging from the single technical parameters of corrugated boxes die cutting machine, the difference between Chinese automatic corrugated boxes die cutting machine and foreign automatic corrugated boxes die cutting machine is very small, but there are certain differences in die cutting speed, precision, stability and reliability. This is mainly limited by the technical level of China’s manufacturing industry. Many parts are processed rough, the error range is relatively large, and the assembly is not accurate enough, resulting in the machine running fast enough and the die cutting accuracy not high enough. For example, the matching and manufacturing accuracy between the intermittent mechanism, the main drive system and the chain row directly affect the improvement of the machine speed. If the assembly accuracy is not enough, it will affect the die cutting accuracy and cause increased noise. Another example is the matching of the toggle pressure mechanism and the moving platform. Due to the existence of relative motion, there must be a gap. If the gap is unreasonably determined, it will cause impact load, vibration, and noise increase, which will affect the speed and accuracy of die cutting.

Factors affecting paper feeding speed and positioning mechanism

At present, the paper feeding method commonly used at home and abroad is continuous feeding, that is, the front sheet and the back sheet are always partially overlapped, and the paper feeding is stable and fast. However, the paper feeding speed is fast, and the paper will produce a great impact force when it is close to the front guide, which will easily cause the paper to curl or bounce, resulting in inaccurate positioning and reduced accuracy. Therefore, the ideal die cutting machine should reduce the speed of the paper on the feeding table as much as possible while ensuring the die cutting speed, thereby reducing the impact of the paper on the front gauge, ensuring accurate positioning, and improving die cutting accuracy.

The printed matter is positioned by the positioning mechanism before die cutting. The positioning mechanism of the die cutting machine is composed of a front gauge, a side gauge, a front gauge mechanism and a back gauge mechanism. The positioning mechanism has a crucial influence on the precision of the die cutting machine.

Before the paper enters the gripper row, it is positioned by the front gauge and the side gauge. The function of the front gauge is to position the paper longitudinally. If there are multiple front gauges installed, only two are used for positioning, and the other front gauges are used for positioning. It must be precisely on the same horizontal line to play an auxiliary role, otherwise, over positioning will occur and the positioning accuracy will be reduced. The height of the front gauge is adjustable. The height of the die cutting positioning should be moderate. If the front gauge is adjusted too high, the front edge of the paper will be bent, which will affect the positioning accuracy; if the front gauge is adjusted too low, the paper cannot reach the front gauge. Positioning does not work. Side gauges are used for the lateral positioning of the paper. There are usually two side gauges, but only one is used for work. In order to ensure accurate positioning, the pressure of the side gauge puller should be appropriate. Too much pressure on the pulling roller will cause the side of the paper to bend; too little pressure may cause the paper not to be pulled in place, affecting the positioning accuracy. In addition, due to the fixed positioning time, the length of the positioning time of the front gauge and the side gauge will also affect the positioning accuracy, which in turn affects the die cutting accuracy. Therefore, the positioning time of the front gauge and the side gauge should be allocated reasonably.

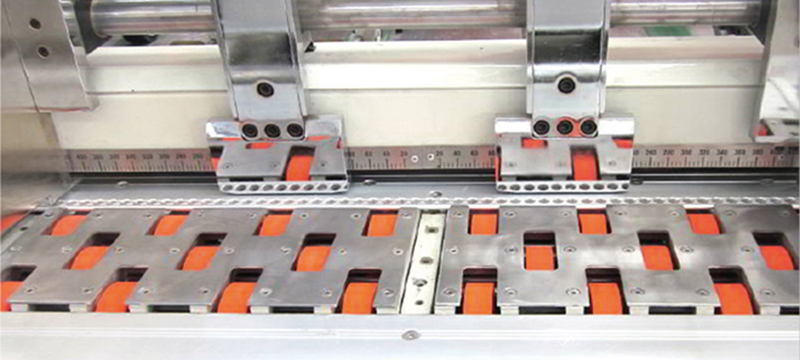

After the paper is positioned, the paper is transferred to the die cutting part by the paper feeder for die cutting and creasing. The paper feeding tooth row is fixed on the intermittent conveying chain, in order to ensure the precision of die cutting, it must stay in the exact position. Therefore, when the paper feeder row moves to the end of the cardboard, the front relief gauge mechanism toggles the feeder shaft to a certain position to complete the front positioning of the paper feeder row. When the conveying chain discharges the paper feeding teeth between the upper platform and the lower platform of the moulding part, the back gauge mechanism moves the teeth row shaft to the positioning point to achieve accurate positioning. Therefore, the front and back gauges directly affect the die cutting accuracy.

Influencing factors of intermittent mechanism, chain and feeding gripper bar of corrugated boxes die cutting machine

The movement of the corrugated boxes die cutting machine is an intermittent movement process, which is controlled by an intermittent mechanism. The intermittent mechanism of the flat die cutting machine generally adopts the parallel indexing cam mechanism. Compared with other intermittent mechanisms, it has the following characteristics: reliable movement; stable transmission; the movement law of the follower depends on the contour shape of the cam; the turntable can achieve ideal expectations To move and obtain good dynamic performance, the positioning of the turntable at intermittent time is completed by the curved groove of the cam, and no additional positioning device is required. When the machine is running at high speed, the cam profile is affected by the speed, acceleration, inertia and direction of the follower, causing the machine to vibrate. This vibration is transmitted to the chain, and the rapid start and stop will cause the jitter of the paper feeder row. , thus affecting the speed and accuracy of the whole machine. Therefore, on the basis of dynamic analysis, the cam profile needs to be dynamically designed to ensure the smooth movement of the intermittent mechanism itself. The chain is a flexible part, and the links are connected by pins, so the error of the pitch is large. When used for a long time, the chain will naturally elongate due to wear, and the error will increase, which will bring unstable factors to the transmission, affect the position of the positioning point of the paper feeding tooth row, and then affect the die cutting accuracy. When working, the chain should not be too tight or too loose. If the chain is too tight, the wear of the chain will speed up and shorten the service life of the chain. If the chain is too loose, the vibration will be violent and the noise will increase.

The paper feeding tooth bar is used to convey the paper. The corrugated boxes die cutting machine mostly adopts solid tooth bar, which is easy to deform during the high speed operation of the machine, thus affecting the positioning accuracy. It will be difficult to stop due to large inertia, which affects the stability of machine operation and the precision of die cutting. Therefore, it is the future development direction to change the solid tooth row into a hollow tooth row with higher hardness. In addition, the gripper will generate noise when working, causing the tooth row to vibrate, thereby affecting the die cutting speed, and also affecting other components.

Usually the following actions can be taken:

(1) The gap between the plugs is as small as possible;

(2) The gripper teeth should be staggered from the rule board;

(3) Adjust the gripper angle appropriately. In addition, the pressure of the grippers will also affect the die cutting accuracy. If the gripper pressure is too large, the paper will be damaged; if the pressure is too small, the paper will slip or slip during the transfer process. Both may cause the paper to be skewed during die cutting.

Influencing factors of chain guide rail of corrugated boxes die cutting machine

In the die cutting process of corrugated boxes die cutting machine, the paper is driven by the chain. In addition to the circular rotation of the chain and the sprocket, the position it passes through is positioned by the guide rail to control the movement direction of the chain and the tooth row. Therefore, when installing and debugging the guide rail, it is necessary to ensure that the thickness of the guide rail is suitable and can be embedded in the chain piece. The distance between the upper and lower guide rails must ensure the smooth passage of the chain. If the distance is too small, it will increase the transmission resistance, affect the transmission speed, and even damage the machine in severe cases. Affect die cutting accuracy. In addition, the track of the guide rail and the length of the chain also have a certain influence on the performance of the machine.

Influencing factors of drive system

The main drive system of the corrugated boxes die cutting machine is driven by the motor to drive the worm and the worm gear. The transmission performance of the main drive system has a direct or indirect impact on the die cutting speed and accuracy. Worm gear is a kind of gear. The gear transmission has the characteristics of stable transmission, strong bearing capacity, good thermal processability and high efficiency. The most common transmission gears are spur gears and helical gears. Compared with the two, helical gears have better stability and larger coincidence coefficient. At present, helical gears are widely used in die cutting machines, but their pressure angle will affect the smoothness of their transmission. When the worm gear and the worm are meshed at the index circle, the backlash between the gear teeth and the gear teeth is suitable, the worm gear is driven smoothly, the lubrication is sufficient, and the worm gear is in the best working condition. Otherwise, if the side clearance is too large, the worm gear transmission will be unstable and cause vibration; if the side clearance is too small, it is not conducive to the flow of lubricating oil and accelerates the wear of gears. Accuracy, which in turn affects die cutting speed and accuracy.

Factors affecting the die cutting part

Die cutting is done under pressure, so the most important part of corrugated boxes die cutting machine is the die cutting part. At present, the most commonly used pressing mechanism in China is the double toggle lever mechanism, which has the transmission characteristics that the movable platform can reach the highest limit position twice during the crank rotation process. During die cutting, the upper platform composed of the upper plate frame and the die cutting plate does not move, and the lower platform gradually rises from the lowest point to the highest point through the main transmission system and the toggle pressure mechanism, and moves back and forth. When the movable platform reaches the limit position, the die cutting pressure is the largest. At this time, the toggle lever is straightened, the pressure will be transmitted to the machine base vertically, and the connecting rod and the crank will not be stressed, which effectively reduces the load peak of the connecting rod and the crank. In order to ensure the quality of die cutting, the entire platform should be uniformly stressed during pressurization, so the working surfaces of the upper and lower platforms must be parallel. Therefore, reasonable design and optimization of the length of the components are particularly important. If the design is unreasonable, it will cause uneven die cutting pressure, excessive idle stroke and other adverse factors, which will affect the speed and accuracy of die cutting.

Factors affecting die, die cutting knife and rubber sponge

The die cutting mechanism is the core of the die cutting machine, and the die cutting plate, die cutting knife, and indentation line are the basic components of die cutting. To ensure high precision die cutting, it is necessary to select high quality die cutting plates, die cutting knives, and indentation lines.

A good die cutting plate is required to have the characteristics of uniform density, light weight, high hardness, good flexibility, easy processing, good flatness, firmness, and not easy to deform. It is also required that the die cutting knife and the indentation line have reliable and stable performance after being embedded in the die cutting plate, and can ensure that the new die cutting knife and indentation line can still be combined with the die cutting plate after multiple replacements of the die cutting knife and indentation line. At present, most large and medium sized printing enterprises in China use laser die cutting and indentation plates. Although this plate is simple and convenient to install, it is prone to deformation due to changes in ambient temperature and humidity, which affects the accuracy of die cutting. In addition, due to the relatively large die cutting pressure, if the layout size is too large, the plate frame is not used or the plate is not firmly installed, it is easy to cause the plate table to move laterally during the production process. In addition, under huge pressure, the core of the horizontal version may be deformed, and the die cutting blade is prone to bending and other undesirable phenomena, resulting in changes in the specifications of the die cutting version and affecting the die cutting accuracy.

With the diversification of packaging materials, products and the emergence of unique packaging designs, high quality die cutting knives for different die cutting materials have become a necessary condition to ensure die cutting accuracy. The quality of the die cutting knife mainly depends on the sharpness of the knife edge, the height error of the entire knife and the bending of the large knife. The sharper the knife edge, the smaller the height error of the whole knife and the smaller the bending of the big knife, indicating that the quality of the die cutting knife is better. In addition, the thickness of the die cutting knife should be uniform. Uneven thickness or exceeding the error range will cause the insert to be difficult, deformed or the cutting line is too loose, thus affecting the die cutting accuracy. The height of the die cutting knife varies with the packaging material being die cut. For example: when the packaging material is double corrugated cardboard, use a high peak knife; when the packaging material is single corrugated cardboard, cardboard or thinner paper, use a low peak knife for better stability.

In order to ensure smooth paper feeding, it is necessary to paste rubber strips at the main cutting lines, and use the elastic restoring force of the rubber strips to push out the embossed printed matter from the knives to prevent the printing material from sticking during the die cutting indentation. When choosing a rubber strip, its height and thickness should be determined according to different products. Usually the height of the rubber strip is about 1 3mm higher than the die cutting blade, and the specific height should depend on the different printing materials. If the rubber strip is too high, it is easy for the rubber strip to touch the warped paper surface first, causing the paper to shift, resulting in inaccurate die cutting. In addition, the hardness of the rubber strip should also be moderate. If the rubber strip is too hard, it will inevitably produce a large extrusion force on the die cutting knife during die cutting, which will deform the blade and affect the quality of the product; if the hardness of the rubber strip is too small, the resilience Insufficient, may cause “paste version” or “scattered version”. Therefore, the thickness and height of the rubber strip should be reasonably selected according to the printing material, and the rubber strip should be pasted in the appropriate position to ensure moderate elasticity and reduce its adverse effect on the die cutting accuracy.

The accuracy of installation and debugging of corrugated boxes die cutting machine also directly affects its production speed, product quality, stability and reliability. Improper installation and debugging will not only reduce the speed and accuracy of the whole machine, but also bring unexpected consequences and troubles to the actual production, so it must be paid enough attention. The quality of machine installation and debugging is also related to the actual operators. Therefore, it is very necessary to actively train employees and improve their quality and technical level.