LKS1060H Automatic Die Cutting Machine For Corrugated Boxes Design Structure Description

LKS1060 Automatic die cutting machine for corrugated boxes can process flat paper, cardboard and corrugated paper. In particular, all kinds of high-grade and exquisite printed matters (such as cigarette boxes, wine boxes, gift boxes, cosmetic boxes, etc.) can be die-cut and indented on this machine, and have obtained three-dimensional, exquisite and beautiful packaging products.

Automatic die cutting machine for corrugated boxes realizes the automation from paper feeding, die cutting, to delivery. The “Human-Machine Interface” is used to display the working speed of the machine, the number of sheets processed, the total running time and working status of the machine; realize the dynamic monitoring of the input points, output points and various faults of the programmable controller, so as to facilitate troubleshooting and operation. more convenient. The preset technical device function can realize the stop of the air pump according to the preset number, and prompt to make a mark (optional); the electronic cam composed of the encoder and the programmable controller is accurate and reliable, and the adjustment is convenient. The frequency converter is used to control the main motor, stepless speed regulation, stable operation, low noise and energy saving. The machine also has automatic fault detection (including detection of double sheets, empty sheets, stacked sheets, falling sheets, etc.), non-stop sampling function, and the die-cutting pressure is large, the registration accuracy is high, and there are many sensors and safety protection devices. Ensure the normal operation of the machine and the safety of personnel.

The main drive system of Automatic die cutting machine for corrugated boxes is equipped with a pneumatic clutch, and a torque limiter (safety clutch) is installed on the main sprocket shaft to avoid injury and damage to operators and equipment due to emergencies, so as to ensure personal safety. and device safety.

Automatic die cutting machine for corrugated boxes is equipped with many safety protection devices in the whole machine. Once the person touches or enters the area, the alarm device will automatically alarm and the equipment will be stopped.

Feeding Section

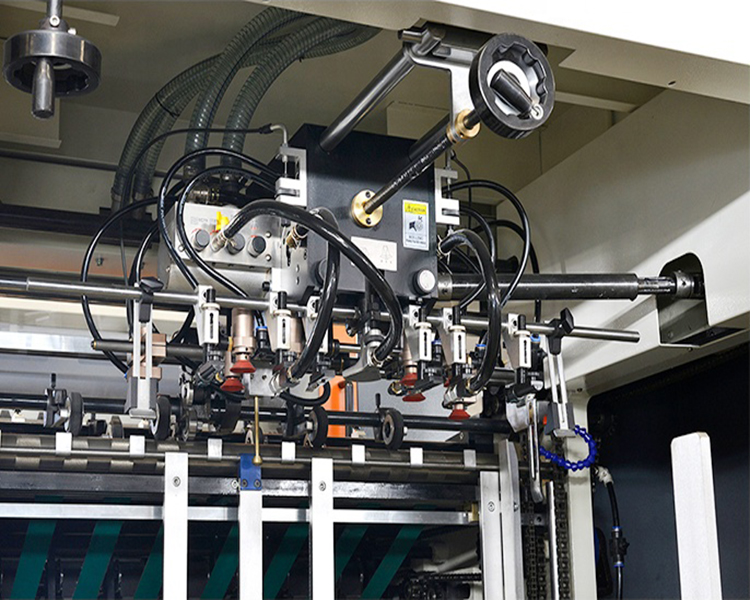

The improved paper jogging device makes the adjustment of the paper push displacement easier and faster.

Four suction and five feeding paper feeding head with 9 suction nozzles, strong suction force and stable paper feeding. The suction nozzles can adjust the angle and suction air volume according to the deformation of the paper, and realize the smooth conversion of thin paper and thick paper.

The main and auxiliary paper feeding mechanism realizes continuous paper feeding without stopping.

Large-screen man-machine interface, PLC program control input and output points and monitoring of obstacles, fast and accurate troubleshooting, very easy to operate.

Host Section

The high-precision chains imported from Germany are pre-stretched and paired one-to-one to ensure the accuracy of each group of tooth row chains.

The high-strength aviation aluminum tooth bar is adopted, and the gripping paper is stable, which can effectively prevent the tooth bar from vibrating. An adjustable device is added to the front and rear positioning of the tooth row, and the positioning accuracy of the tooth row can be fine-tuned and compensated for the wear error of the main chain or parts.

The key components that bear the die-cutting pressure, such as the upper platform, the moving platform, and the bottom platform, are integrally cast with pressure-resistant high-strength ductile iron at high temperature, and after a long time of stress relief tempering and aging treatment, it can ensure that the high-pressure die-cutting is used. No deformation, stable pressure.

The main drive adopts large modulus worm gear and worm drive, and is connected in the form of crankshaft, pendulum rod, connecting rod and bearing bush, which reduces the movement gap and enables the machine to maintain stable operation at high speed.

Intermittent and Lubrication

Use the intermittent, optimized motion curve and drive angle (230°) of Taiwan professional divider manufacturers with large torque and high positioning accuracy to improve the smooth running of the paper and the positioning accuracy, durable, and the intermittent mechanism is equipped with a torque limiter to ensure The safety of the machine in the case of abnormal torque of the host chain and intermittent.

The oil storage lubrication system controlled by PLC is used for intermittent lubrication to ensure timely and uniform lubrication.

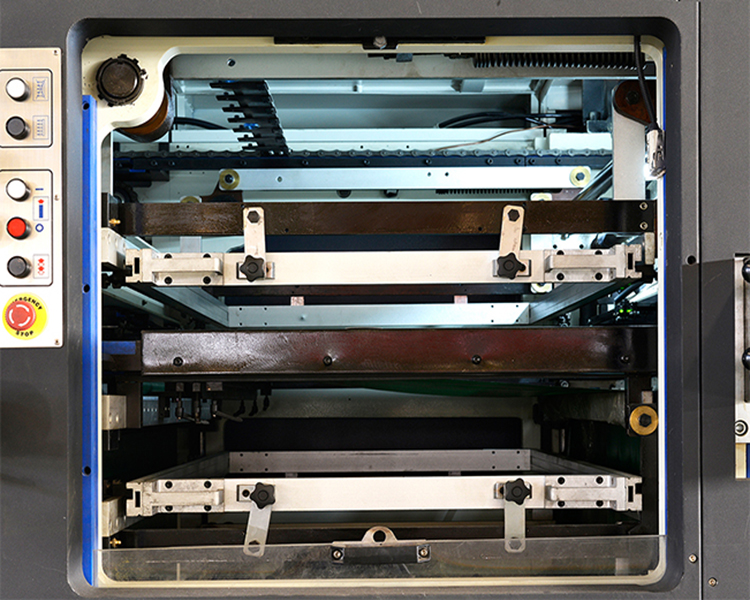

Strippping Section

This die cutting machine is strippping with three frames, the upper frame and the lower frame are withdrawable, and the middle frame has a tooth row positioning device to effectively improve the accuracy.

Electrical Section

A Takasaki 11kW main motor provides the capacity.

Japanese Izumi integrated buttons and knobs.

PLC human-machine interface, the working speed of the display, the number of processed sheets, the total running time and working status of the machine; the dynamic monitoring of various faults of the input points and output points of the programmable controller is very convenient for troubleshooting and operation; The preset technology function can stop the air pump according to your preset number and prompt you to make a mark; the electronic cam formed by the encoder and the programmable controller is more reliable and easy to adjust

The main motor is controlled by a more user-friendly frequency converter and variable frequency speed controller, with stepless speed regulation, stable operation, low noise and energy saving.

This machine is equipped with more sensors and safety devices to ensure the normal operation of the machine and personal safety.

Delivery Section

Sectional adjustable brush and paper flattening blower to stabilize the finished product in the delivery section. Paper delivery blower device, paper delivery is smooth and neat.

The main delivery mechanism and the auxiliary delivery mechanism are quickly switched, which effectively saves manpower.

The delivery blower device makes delivery smooth and tidy.

The delivery mechanism and the auxiliary delivery mechanism are quickly switched, which effectively saves manpower.

Main technical parameters of Automatic die cutting machine for corrugated boxes:

Scope of application of paper: die-cutting and creasing of flat paper corrugated paper, suitable for die-cutting and creasing and cold-pressing embossing of carton, carton, and paper trademark PVC film, cardboard 0.1-2.5mm, corrugated paper ≤4mm

Maximum paper size: 1060×760mm

Minimum paper size: 400×370mm

Feed stack height: 1550mm

Delivery stack height: 1400mm

Die cutting size: 1060×760mm

Inner size of plate frame: 1100×790mm

Die-cut steel plate size: 1080×780mm

Die cutting pressure: 300T

Maximum speed: 7000 times/hour

Total power: 18KW

Voltage: 380V

Mechanical net weight: 18T

Gross weight: 18.5T

Machine size: 7800×3990×2300 (including foot pedal precoding paper)