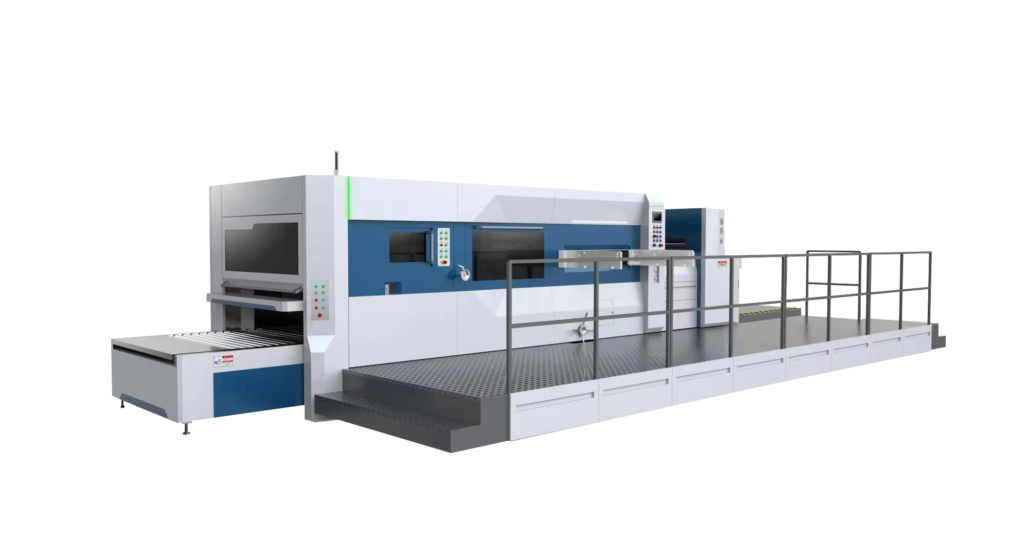

How to maintain flat die cutting machine with stripping

Most flat bed automatic die cutting machines with stripping device.And most of the stripping is done by stripping needles, and some are done by using wooden stripping boards. The wooden stripping version is easy to use, and the stripping effect is better than the stripping needle, which is of great help to improve the speed of the machine.

Pay attention to the following points when stripping:

① Try not to open joints on the waste that needs to be removed.

② Ensure that the size of the stripping hole is appropriate. If the stripping hole is too large, the entire die-cut product will be scattered during stripping; if the stripping hole is too small, it will not be cleared. Generally speaking, it is more appropriate for the stripping hole to be 1.5-2.0 mm larger than the waste material.

③ You can also add some loose sponges on the stripping plate, and press the paper during stripping to prevent the paper from spreading after die cutting. Generally, the paper delivery part of the die-cutting machine with a stripping device has few problems, and the paper delivery part of the die cutting machine without a stripping device is prone to uneven paper delivery, scattered paper and other phenomena that are not easy to clean. There are ways to solve it, but it will affect the efficiency of die cutting.

The flat bed automatic die cutting machines with stripping process will develop towards high speed, high precision, high reliability, and humanized machine operation. Operators in packaging and printing factories need to keep up with the development trend, master related technologies, and be in production Continuous accumulation in order to ensure the perfect die-cutting quality and improve the grade of products.