1450High speed automatic folder gluer machine

Product Description

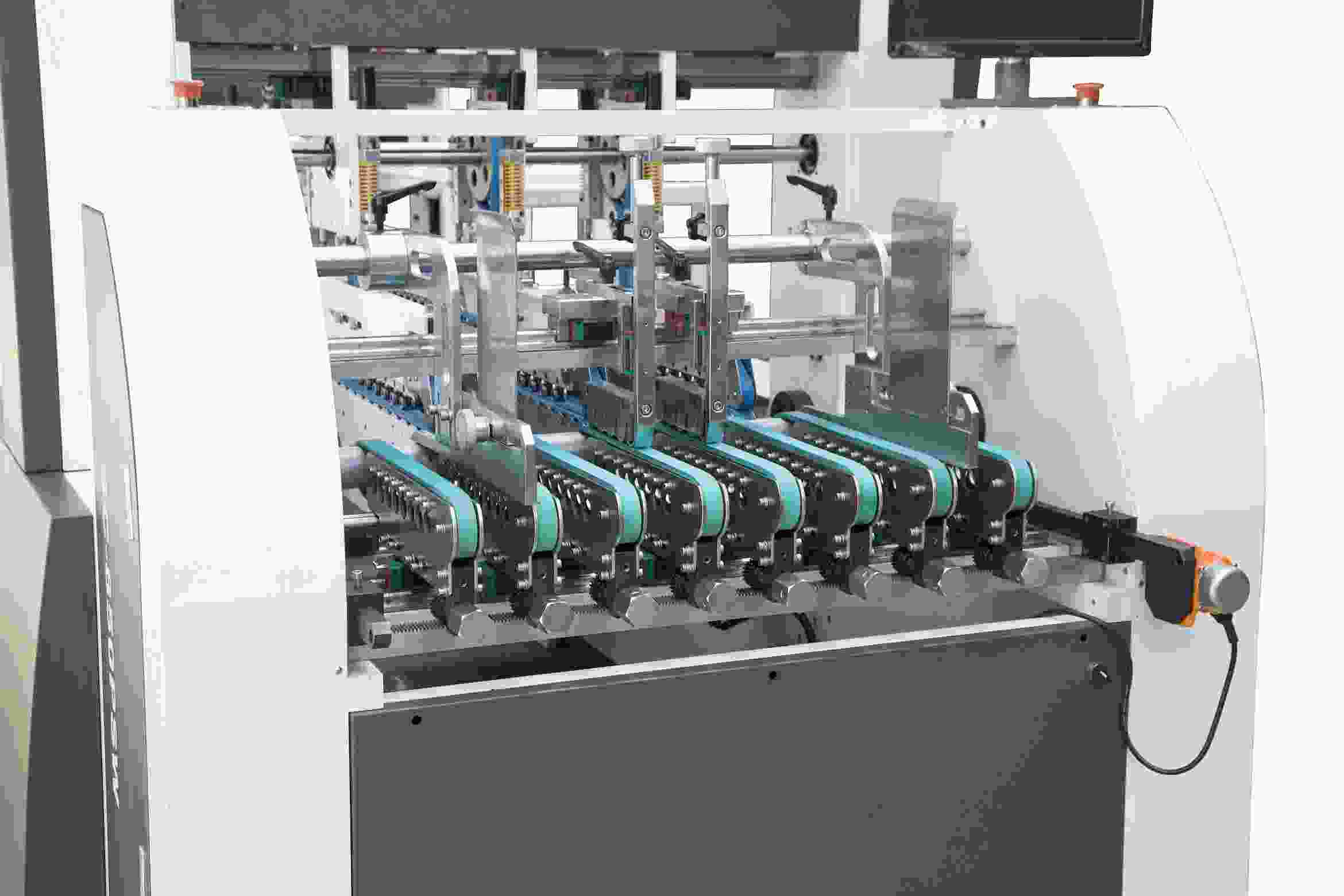

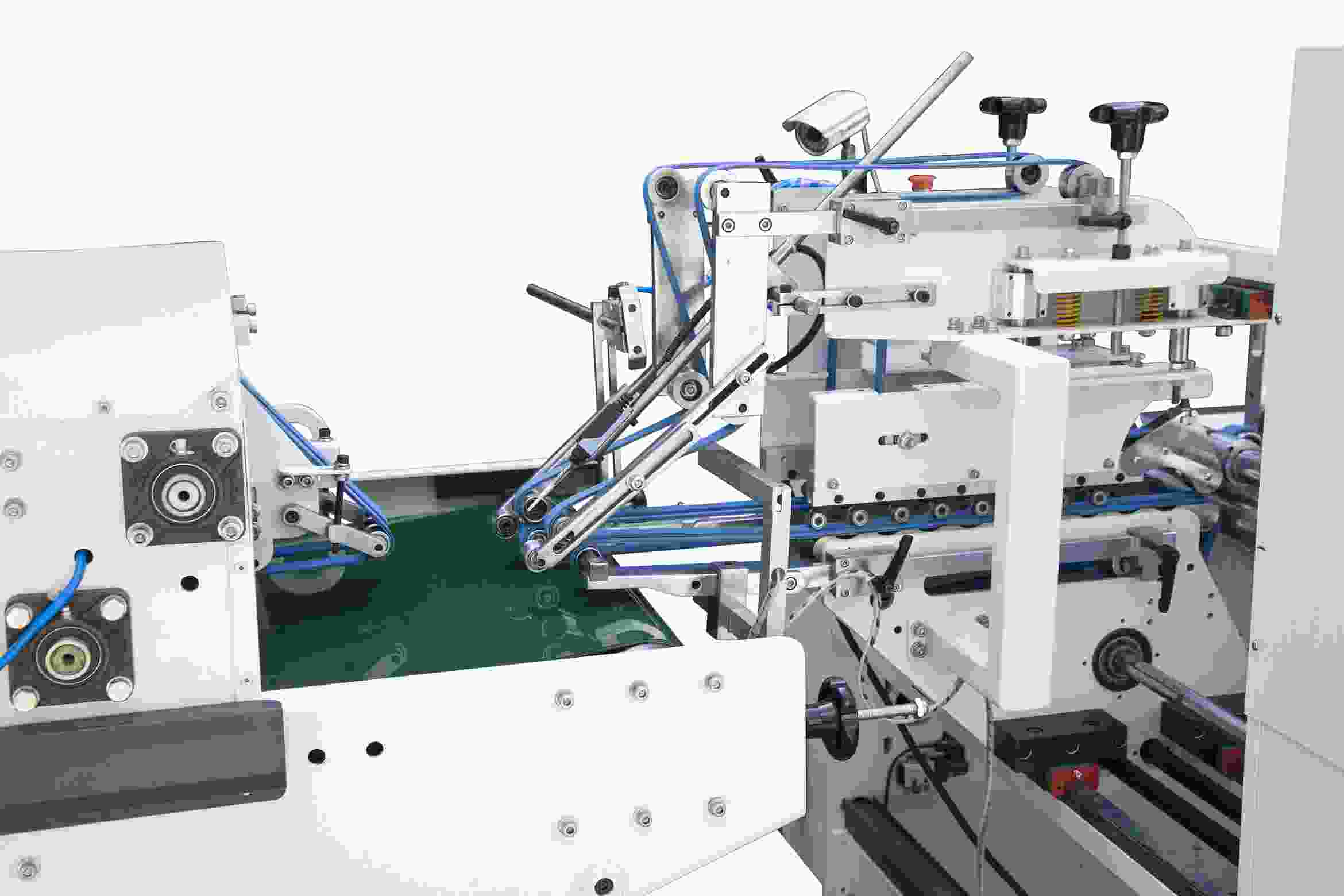

- Remote control through whole machine to give user-friendly and easy set-up

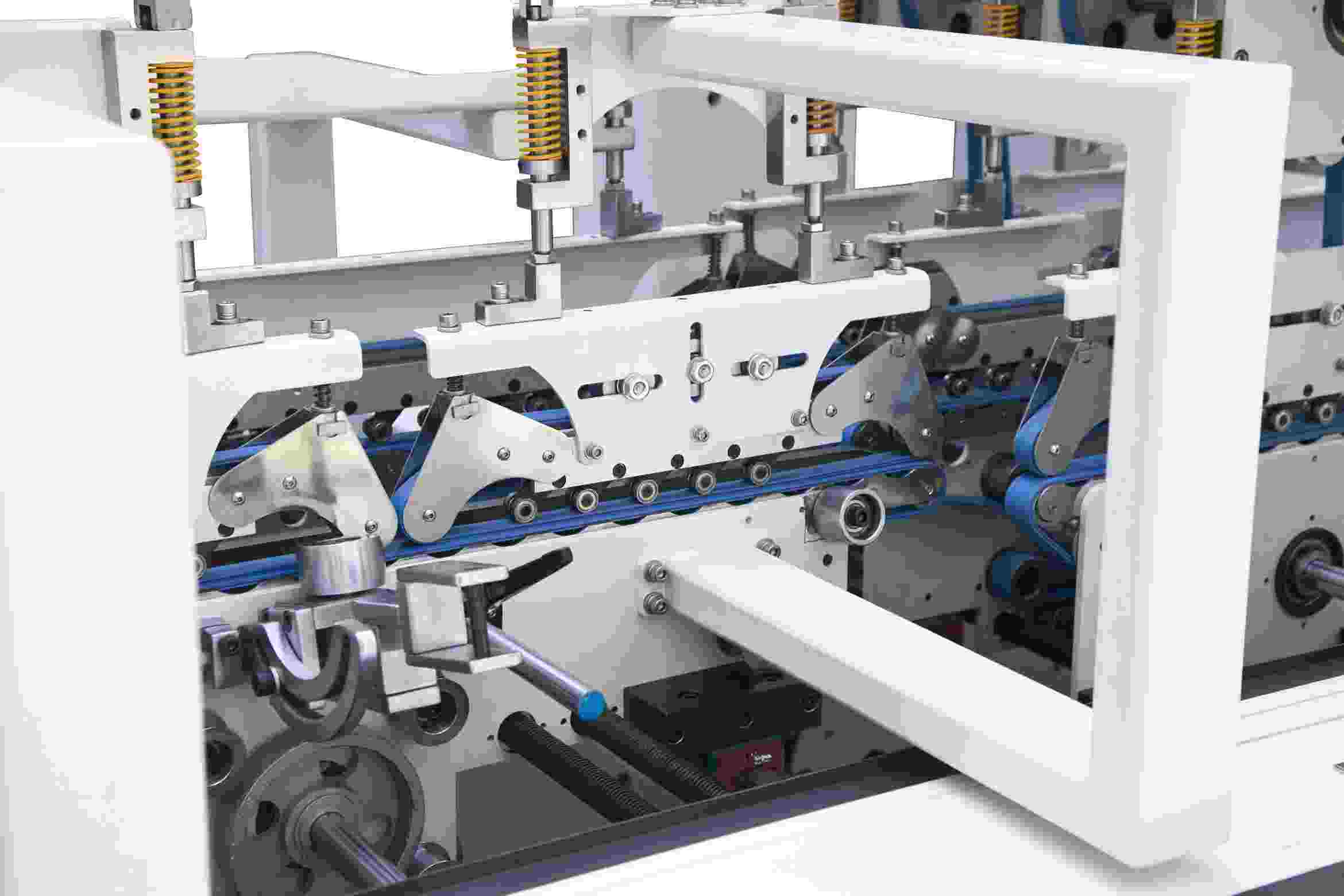

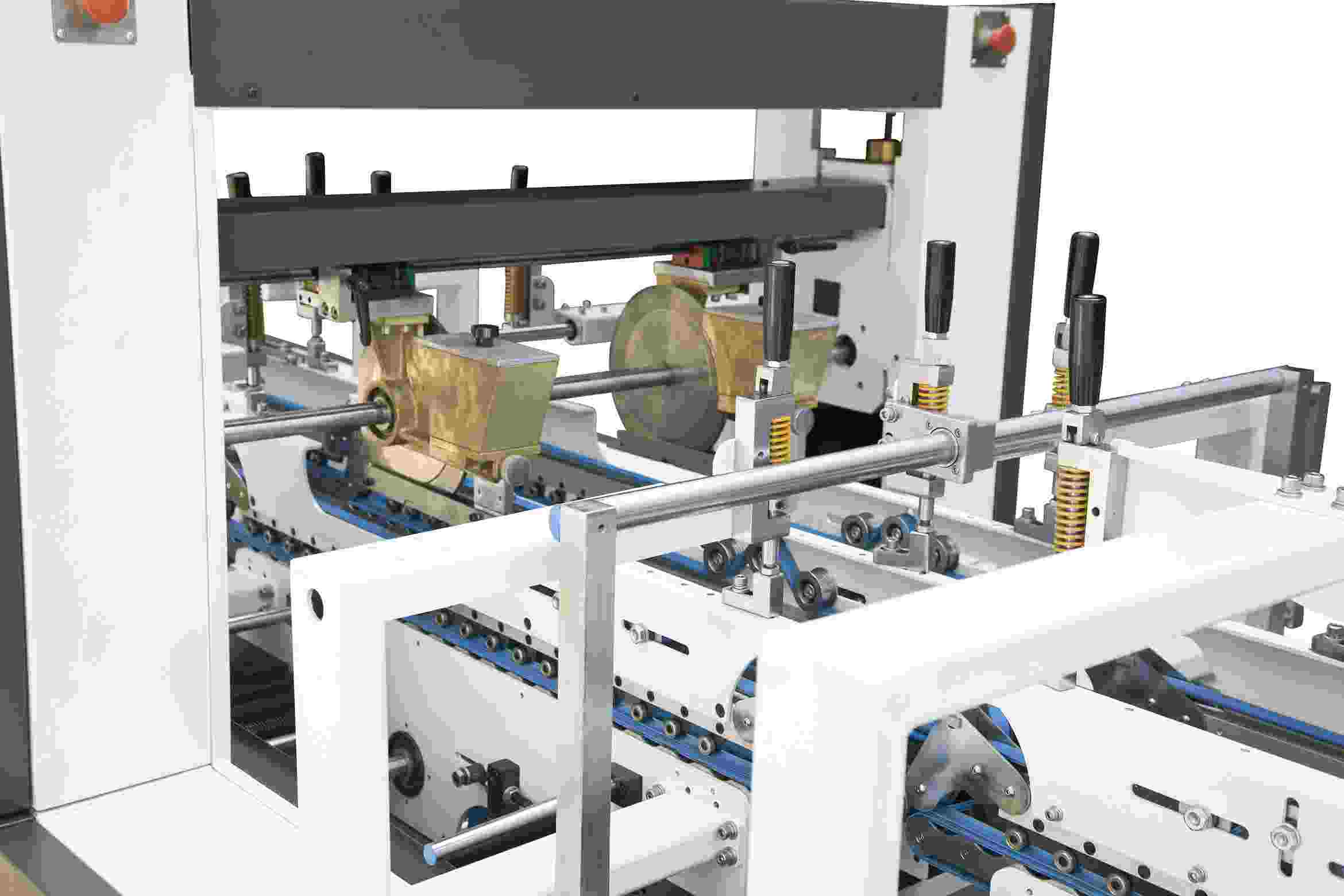

- Modular design ready for upgrade in the future for job demanding

- All the transmission belts of the lower panels are wrapped around externally when replacing the belt, there is no need to unload the transmission shaft , it is simple and easy to replace.

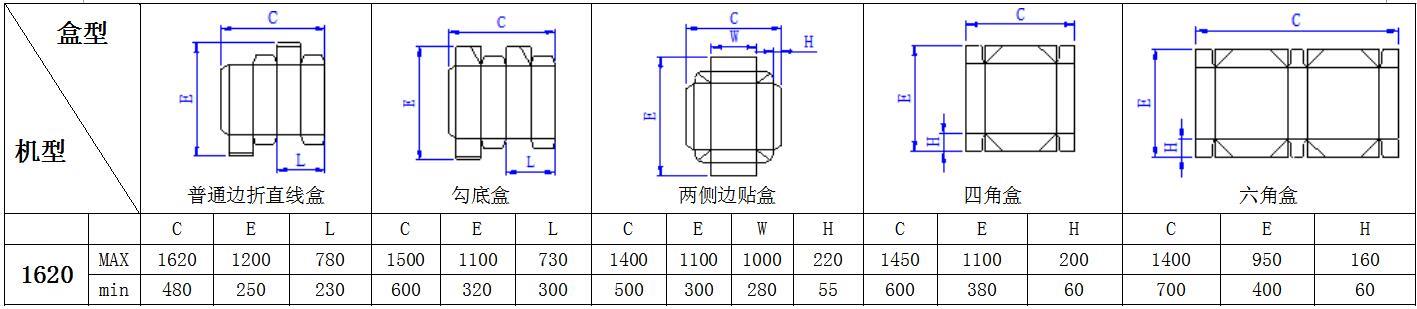

- To meet various kinds of order demand in the future, the standard machine can be advanced by adding other optional units such as, regulator, pre-folder, 4& 6 corner attachment, panel movement by Motorization to achieve its highest efficiency