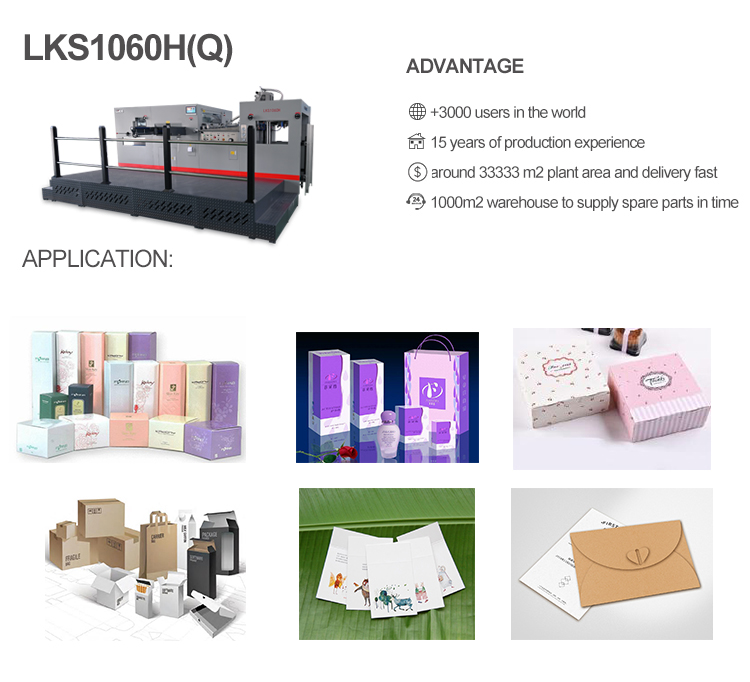

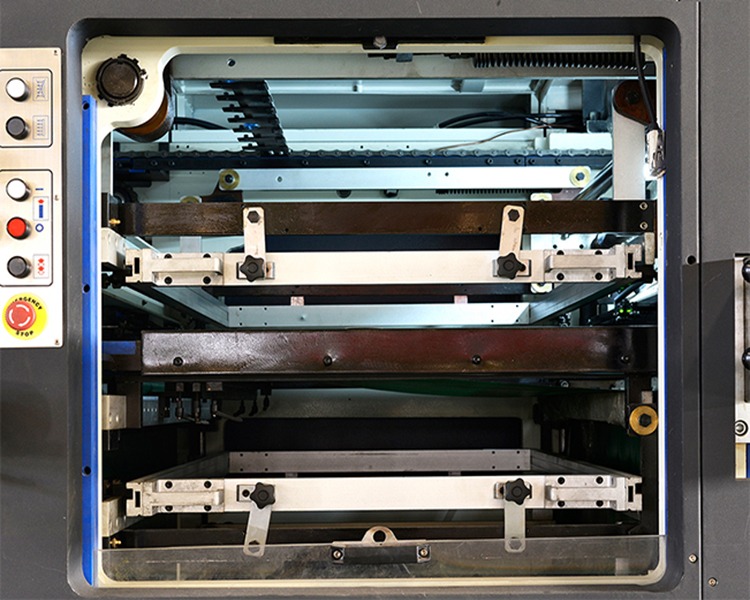

LKS-1060H(Q) High Speed Automatic Corrugated Die Cutting Machine

Product Description

Model: 1060H(Q) Automatic Corrugated Die Cutting Machine

Product Description:

LKS1060 Automatic Corrugated Die Cutting Machine can process flat paper, cardboard, corrugated paper and PVC, etc. It is suitable for die-cutting indentation and cold-pressed embossing of cartons, cartons, paper labels, etc. In particular, all kinds of advanced and exquisite printed matter (such as cigarette boxes, wine boxes, gift boxes, cosmetic boxes, etc.) can be die-cut and indented in this machine.

Characteristics:

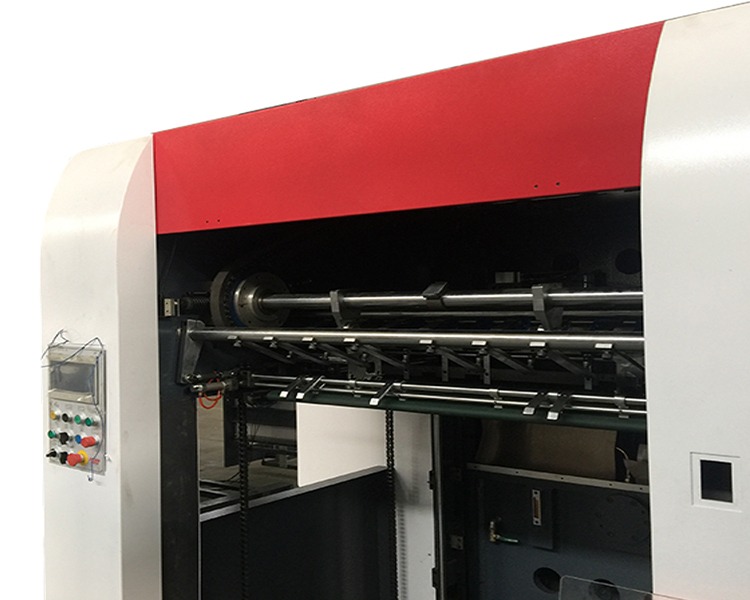

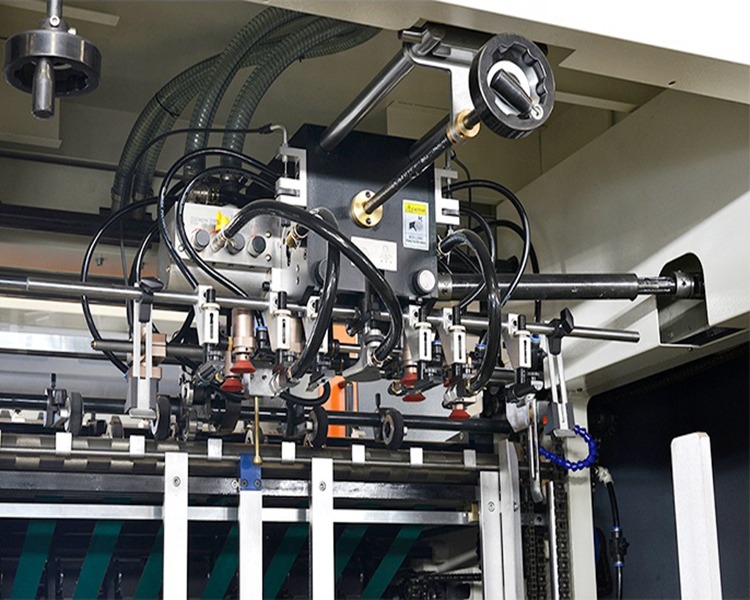

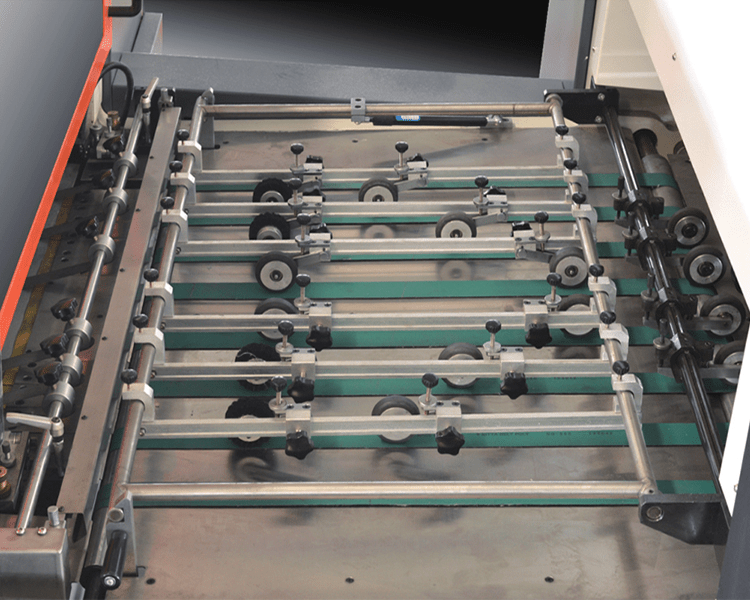

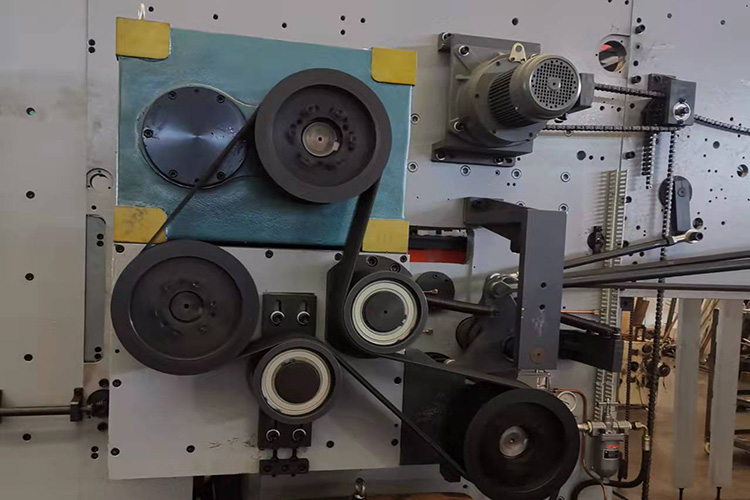

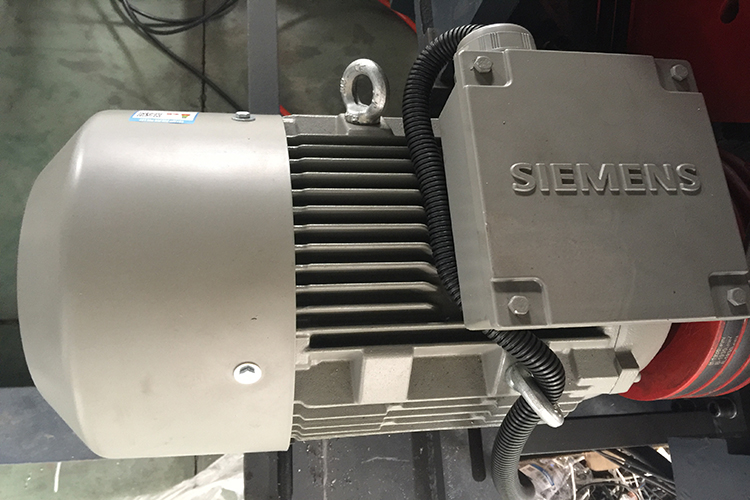

Automatic corrugated die cutting machine realizes the automation from feeding, die cutting, to delivery. The “Human-Machine Interface” is used to display the working speed of the machine, the number of sheets processed, the total running time and working status of the machine; the preset counter function can realize the stop of the air pump according to the preset number, and automatically mark it. The electronic cam composed of the encoder and the programmable controller is accurate and reliable, and the adjustment is convenient. The frequency converter is used to control the main motor, stepless speed regulation, stable operation, low noise and energy saving.