LKS-800H(Q) Automatic Die Cutting Machine with Stripping

Product Description

Model: LKS-800H(Q) Automatic Die Cutting Machine with Stripping

Description:

Automatic die cutting machine with stripping is a special equipment developed by our company in combination with the superior performance of similar products at home and abroad, which is suitable for high end color box and color box die cutting.

Characteristics:

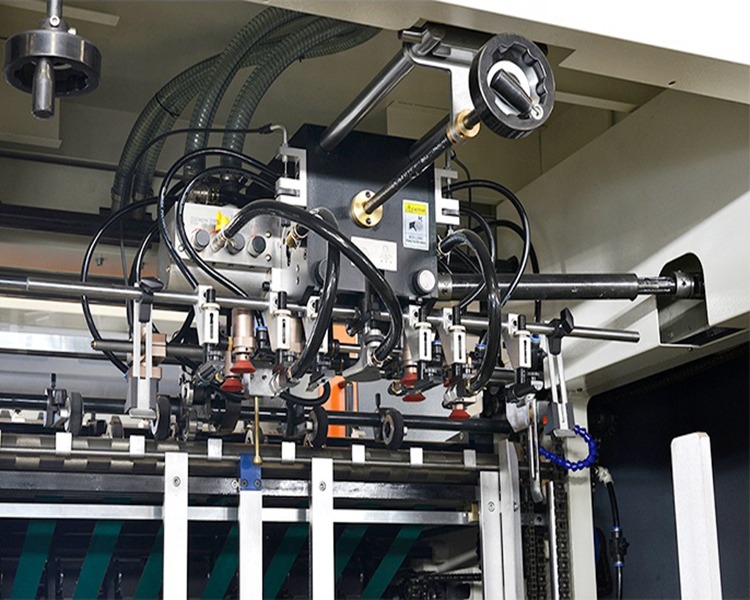

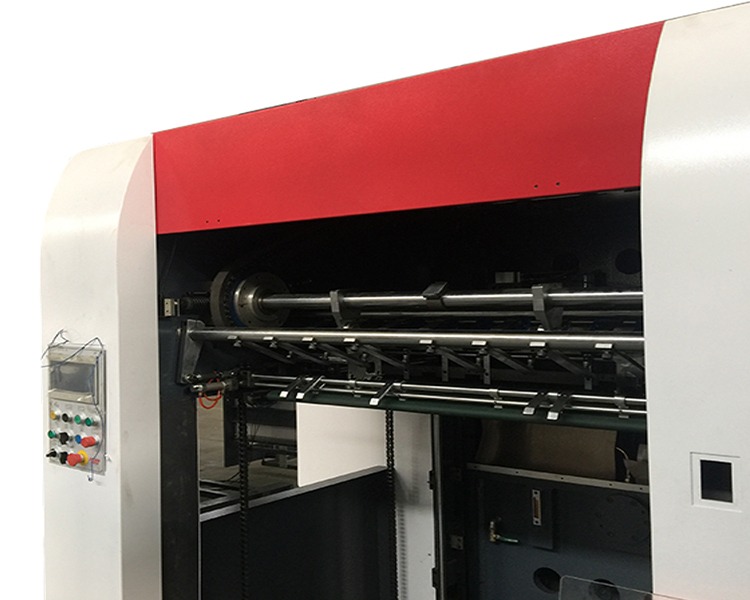

This machine uses high strength gripper row, and the advanced open grip gripper mechanism can adapt to various types of cardboard, cardboard and corrugated paper.

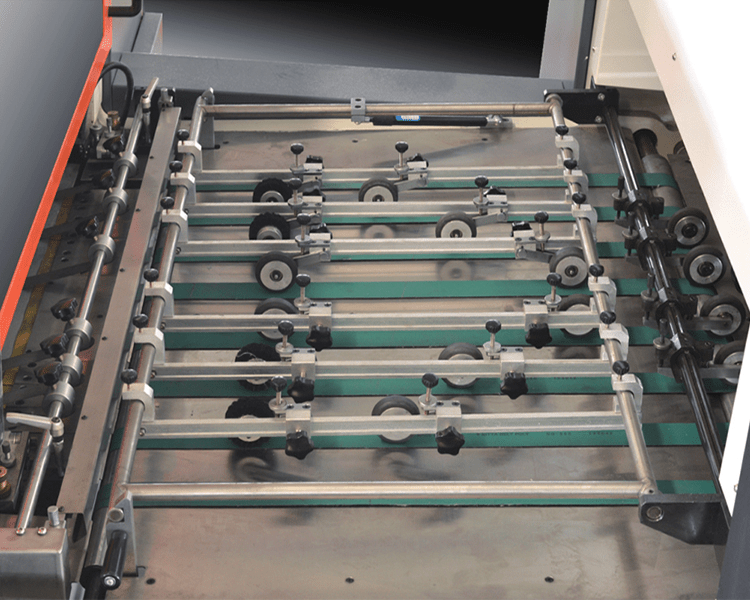

The front and rear positioning and side positioning mechanisms ensure the die cutting accuracy of the paper. It has a high-precision intermittent mechanism.

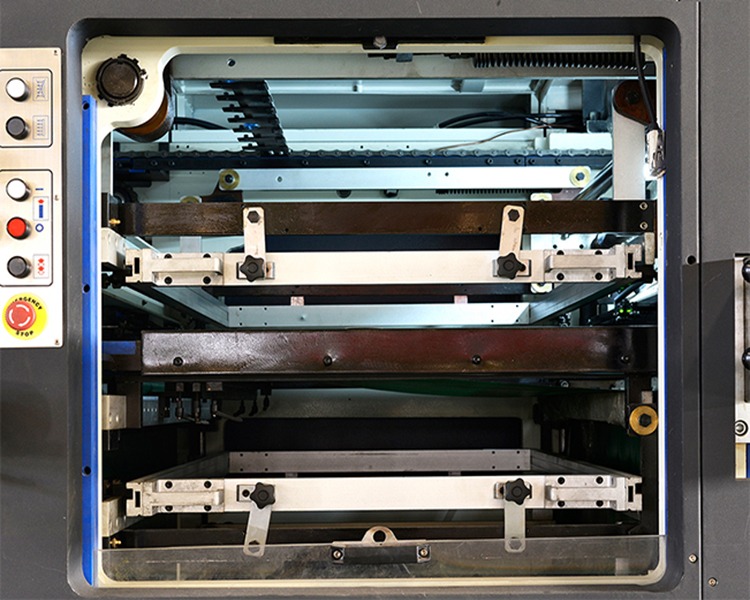

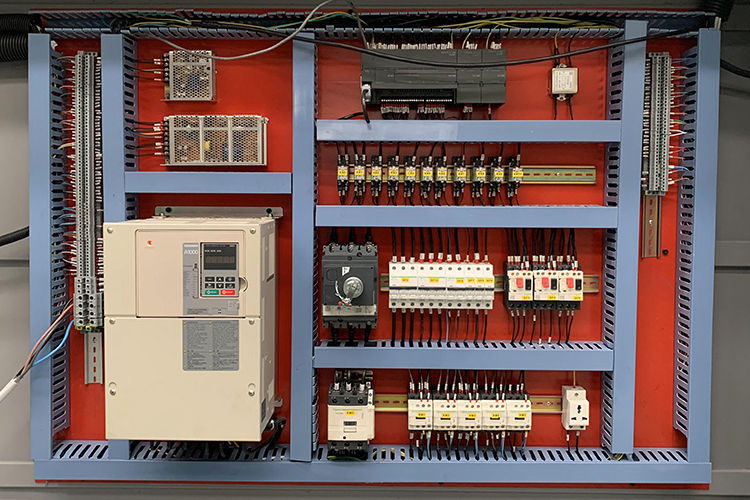

Fast acting pneumatic clutch, pneumatic locking plate. Pneumatic suspension of the bottom plate, using programmable controller and man machine interface, digital display of the machine’s working speed, number of sheets, and total running time; the man machine interface dialogue can display the machine’s faults, making troubleshooting very convenient.

The frequency converter is used to control the stepless speed regulation of the main motor, and the operation is stable.

The machine is equipped with sensors and safety devices in many places to ensure the normal operation of the machine and personal safety.

The die cutting pressure is easy to adjust, and it can perform selective die-cutting without jaws, making this machine a cost-effective product.