Automatic Foil Stamping &Hot Embossing & Die Cutting Machine

Product Description

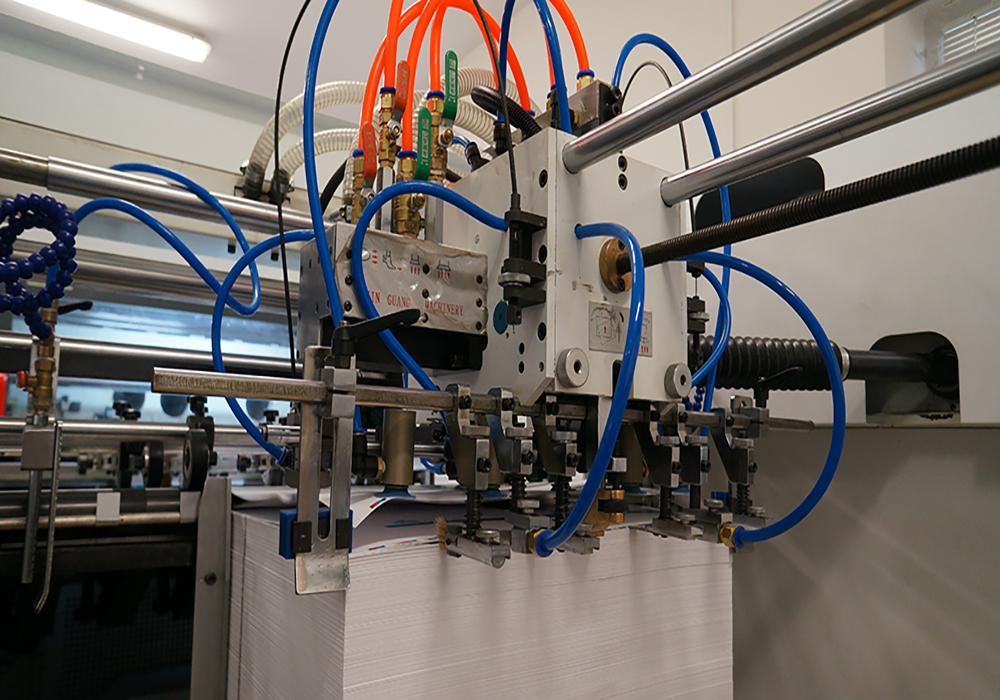

Model: 1060T Automatic Foil Stamping Die Cutting Machine

Description:

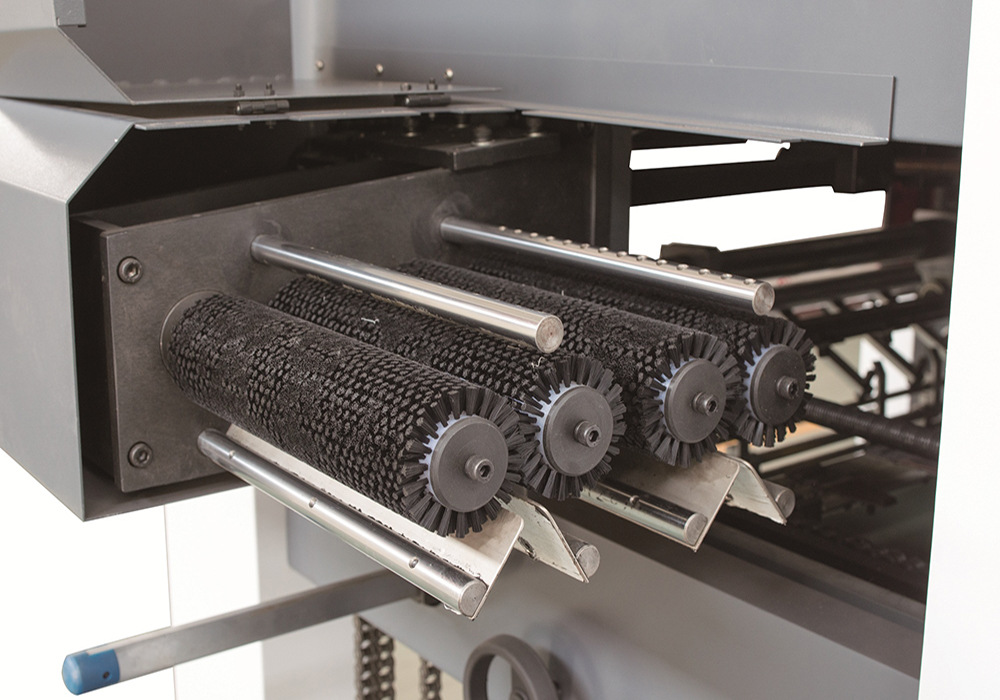

The Automatic Foil Stamping Die Cutting Machine is the key equipment for the production of cartons and high-standard paper products. It is especially suitable for automatic die cutting and peeling of complex cartons and cigarette cartons to rationalize the production of cartons. The Automatic Foil Stamping Die Cutting Machine is assembled, transported and installed as a whole, and can be put into use in one day, reducing costs. Sophisticated assembly and high configuration make it superior to Taiwanese machines and to compete with Japanese machines.

Features:

All cutting components of the Automatic Foil Stamping Die Cutting Machine are designed to be stable without any messy work or restricted material. The wall plate is formed of cast steel, with high anti-deformation and tensile strength, the wall plate thickness is 100mm, and the total wall thickness is 265mm. The maximum pressure of the machine can reach 580 tons. The crankshaft is made of fully hardened chrome steel, the large worm wheel and all bearing bushes are made of alloy copper, and the thickness of the worm wheel is 90mm (commonly used 65mm). The worm is ground by hardened bearing steel (45# carbon steel is generally not ground). All other components are at least made of standard 45# steel, and all the above components are directly manufactured by our company.

Introduction:

Lukes Machinery is one of the leading manufacturers of Automatic Foil Stamping Die Cutting Machine in China, our LKS1060T Automatic hot foil stamping die cutting machine has high quality with competitive price ,which is good reputation for sales in market.