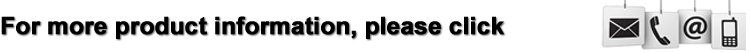

TYS Series Box Stitcher

Product Description

Box Stitcher is the last process equipment for manufacturing cartons.

It is mainly used for stapling of single corrugated cardboard forming to meet the requirements of multi-variety and different batch production.

It is suitable for the packaging needs of food, cotton spinning and other export products, and is currently the ideal carton equipment.

The machine has the advantages of high production efficiency, low labor intensity, easy operation, stable performance, reliable operation, etc. It is a practical equipment in the packaging carton industry.

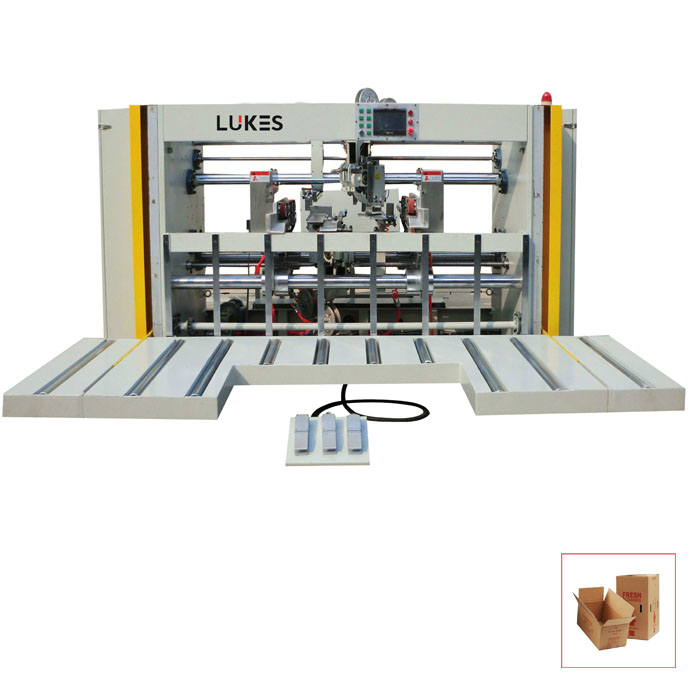

Box Stitcher Main parts details:

1. Japan Yaskawa Servo

2. Taiwan Tiande switch, travel switch, Taiwan Yangming proximity switch, Taiwan Shihlin contactor

3. Taiwan Wellun touch screen

4. Germany Siemens PLC, module

5. Nail head blade and bottom mold are made of German tungsten steel (wear resistance)

6. Taiwan Jaguar Air Compressor

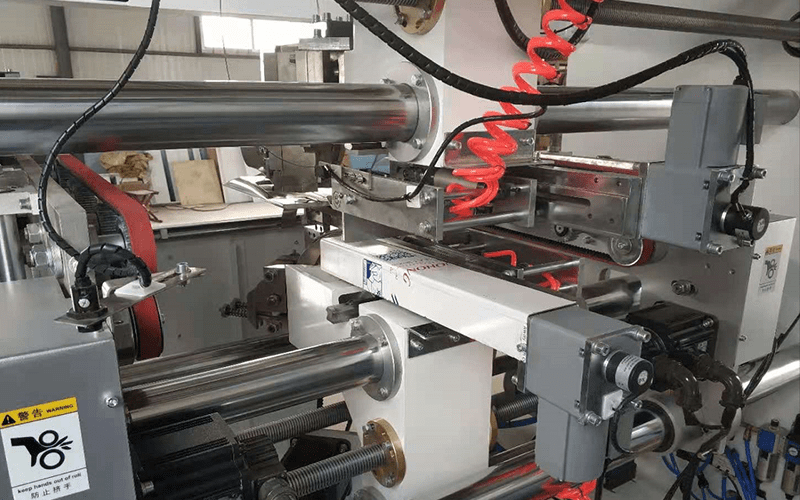

Box Stitcher Features:

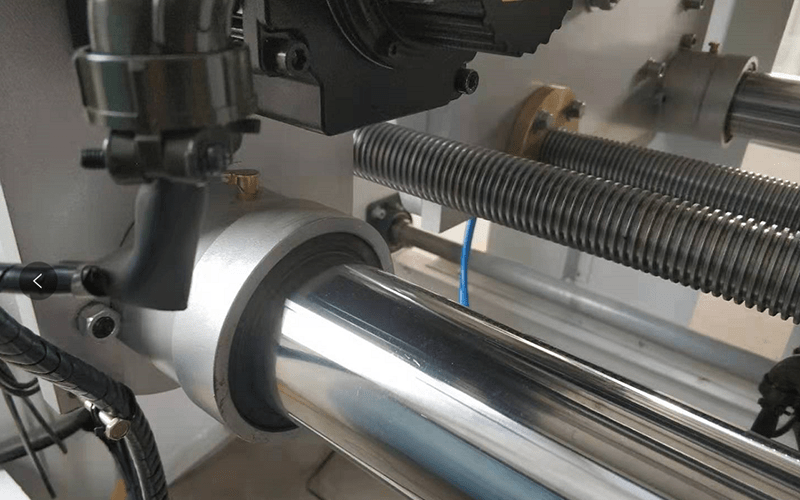

1.Double servo drive, accurate precision, reduced mechanical transmission parts, which can effectively reduce the mechanical failure rate.

2. Automatic baffle, convenient and time-saving, easy to operate.

3. Touch screen operation, parameters (nail distance, number of nails, type of nails, rear baffle) can be changed easily and quickly.

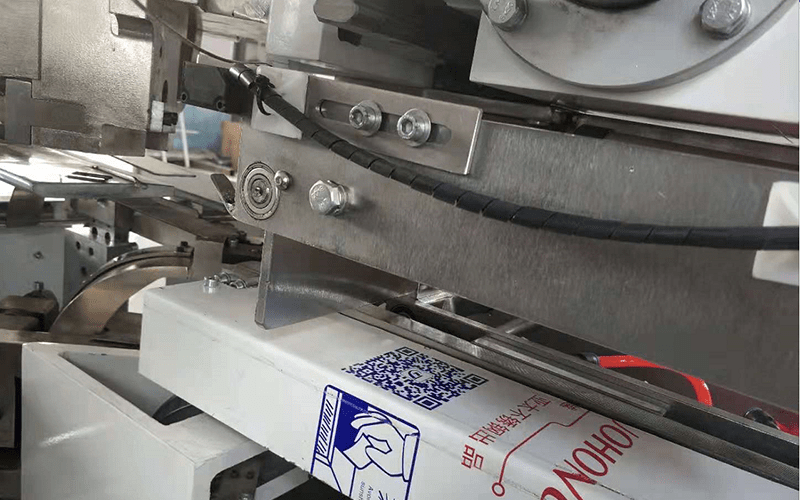

4. It can be nailed with single nails (/ / /), double nails (// // // ), and reinforced nails (// / //), which are suitable for customers’ requirements for nail types.

5. It only takes one minute to change the size.

6. The feeding part automatically counts (0-999), and automatically sends out after bunching, which is convenient for bundling.

7. Can be nailed with lid box and without lid box. (The shortest distance from the first nail to the edge of the carton is 25mm)

8. Automatic alarm device when the staple thread is used up. (Avoid missing nails and defective products with less nails produced by nailless lines)

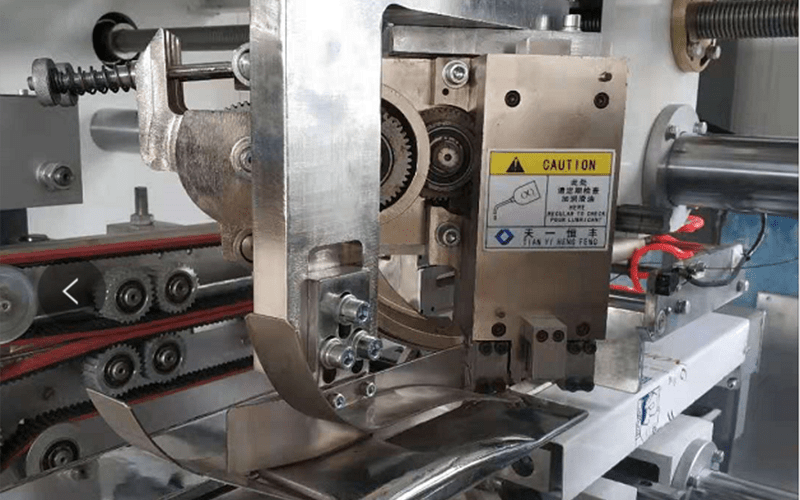

Mechanical advantage:

1. Single nail, double nail, strengthen nail can be stitched one time.

2. Size was controlled by electric ,fault was showed on the screen.

3. Suit for 3/5 /7 ply offset carton and cover or no cover was stitched.

4. The frame undergoes integral processing and stress relief annealing to ensure precision and stability.

5. Machine speed: 500 Stitches/Minute with regular distance.