ML1100 Die Cutting Punching Machine

Product Description

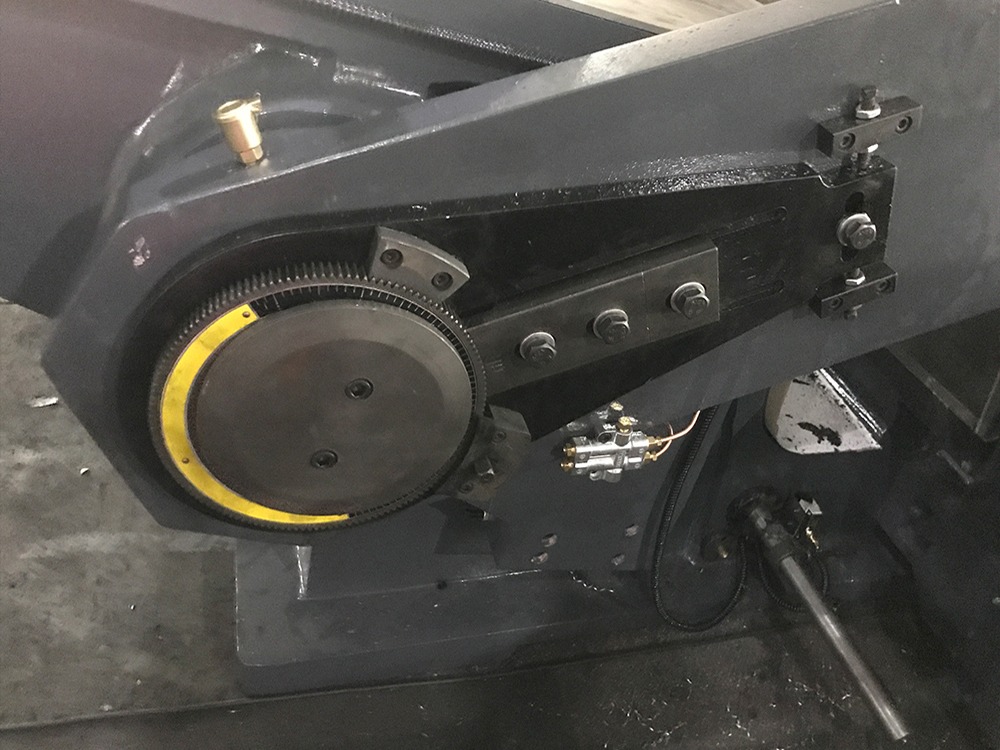

Model: ML1100 Die Cutting Punching Machine

Application:

Die Cutting Punching Machine is a special equipment for die cutting and creasing all kinds of ordinary cardboard, corrugated cardboard, plastic sheet and leather products. It is suitable for printing, packaging and decoration, and plastic industries.

Features:

1. The sliding bearing is made of copper alloy, which is wear resistant and damped.

2. The flywheel torque is large, and the pressing force is large.

3. The body of the die cutting punching machine adopts H250 integral casting, which has high strength and good rigidity.

4. The single plate electromagnetic clutch is sensitive and reliable.

5. It has three functions of single sheet pressing and cutting, continuous pressing and cutting and opening delay, and the delay range can be adjusted at will.

6. The operating height is designed reasonably, and the opening angle of the press frame is large.

7. The main electrical appliances of die cutting punching machine adopt imported electrical appliances, and the safety protection system is reliable.

8. It can be equipped with internal and external movable plate frame and centralized refueling device.

Advantage:

The flywheel torque is large, the structure is reasonable, the pressing force is large, and the application range is wide, and it has a good effect on various complex die-cutting products. Die cutting punching machine has the advantages of compact structure, excellent manufacturing, large pressing force, high precision, convenient use, safe and reliable operation and so on.