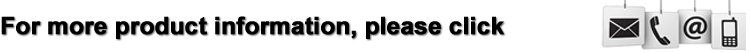

LKS1320SZ(Q) Auto and Manual Die Cutting Machine

Product Description

Model: LKS1320SZ(Q) Auto and Manual Die Cutting Machine

Describe:

Auto and manual die cutting machine (Tiptronic die cutting machine) is designed with efficient and fast die cutting. According to different paper types, the paper feeding method can be freely converted between automatic feeder feeding and semi-automatic manual feeding. Using pneumatic and electric functions, it can perfectly realize the rapid replacement of jobs and effectively improve work efficiency.

Features:

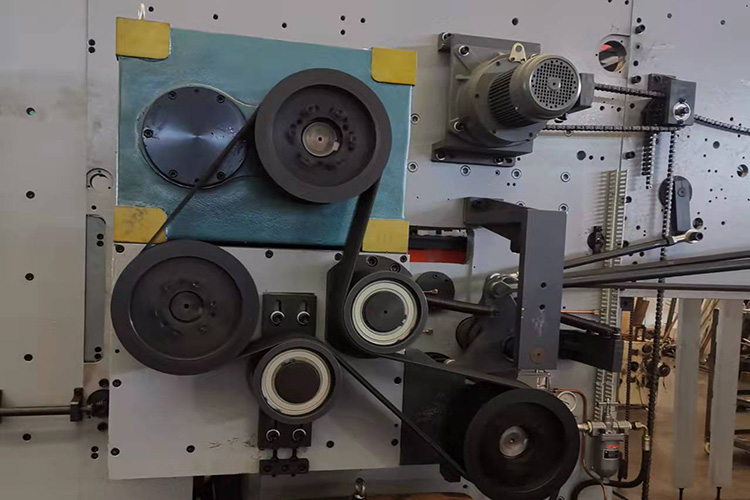

Auto and manual die cutting machine applies the most advanced structural design from the design of the whole machine to the treatment of fine parts, from paper feeding, paper feeding to die cutting, waste removal and paper delivery, from appearance design to safety standards. The best imported components have changed the previous optional structure to the standard configuration, and comprehensively improved the speed, accuracy, stability and safety.