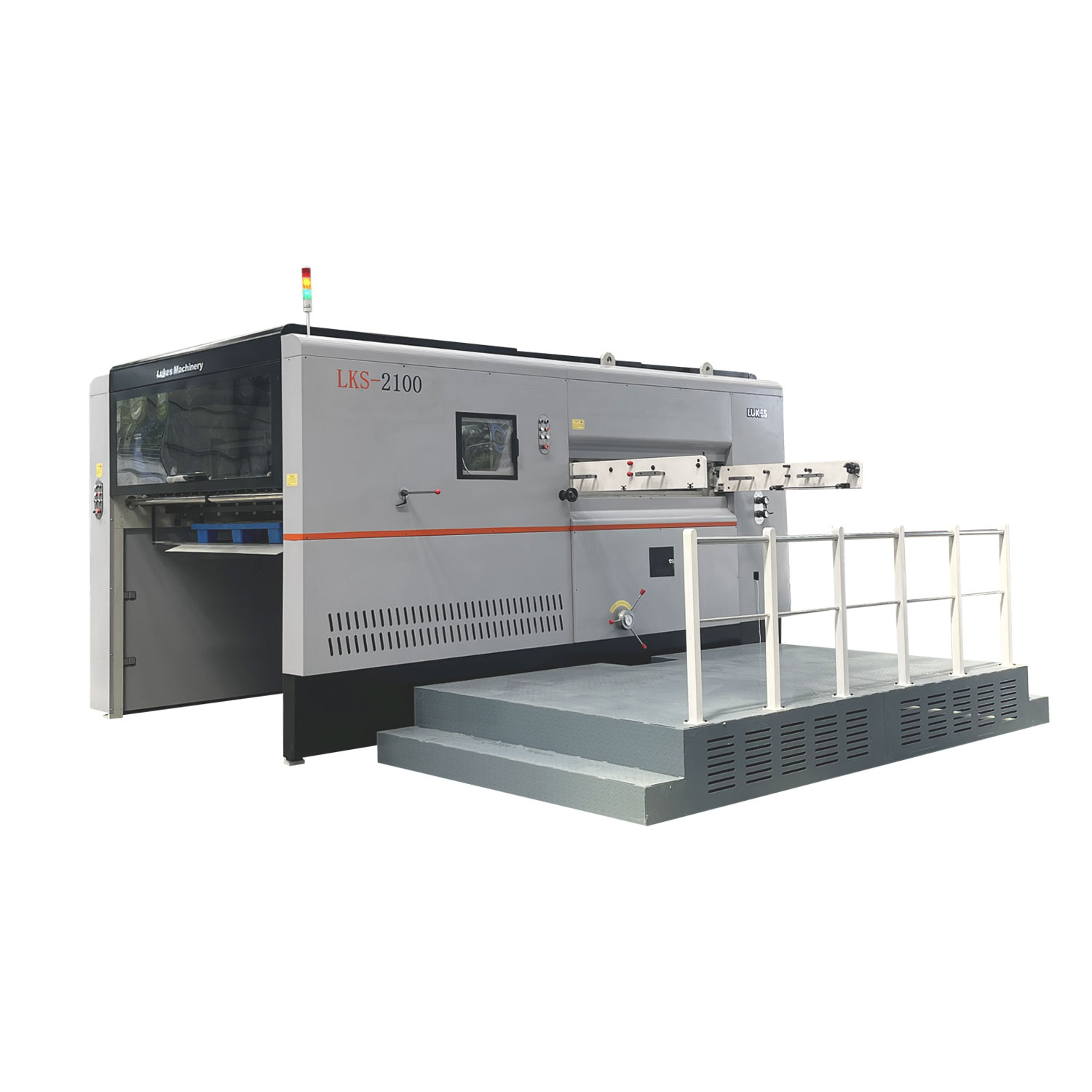

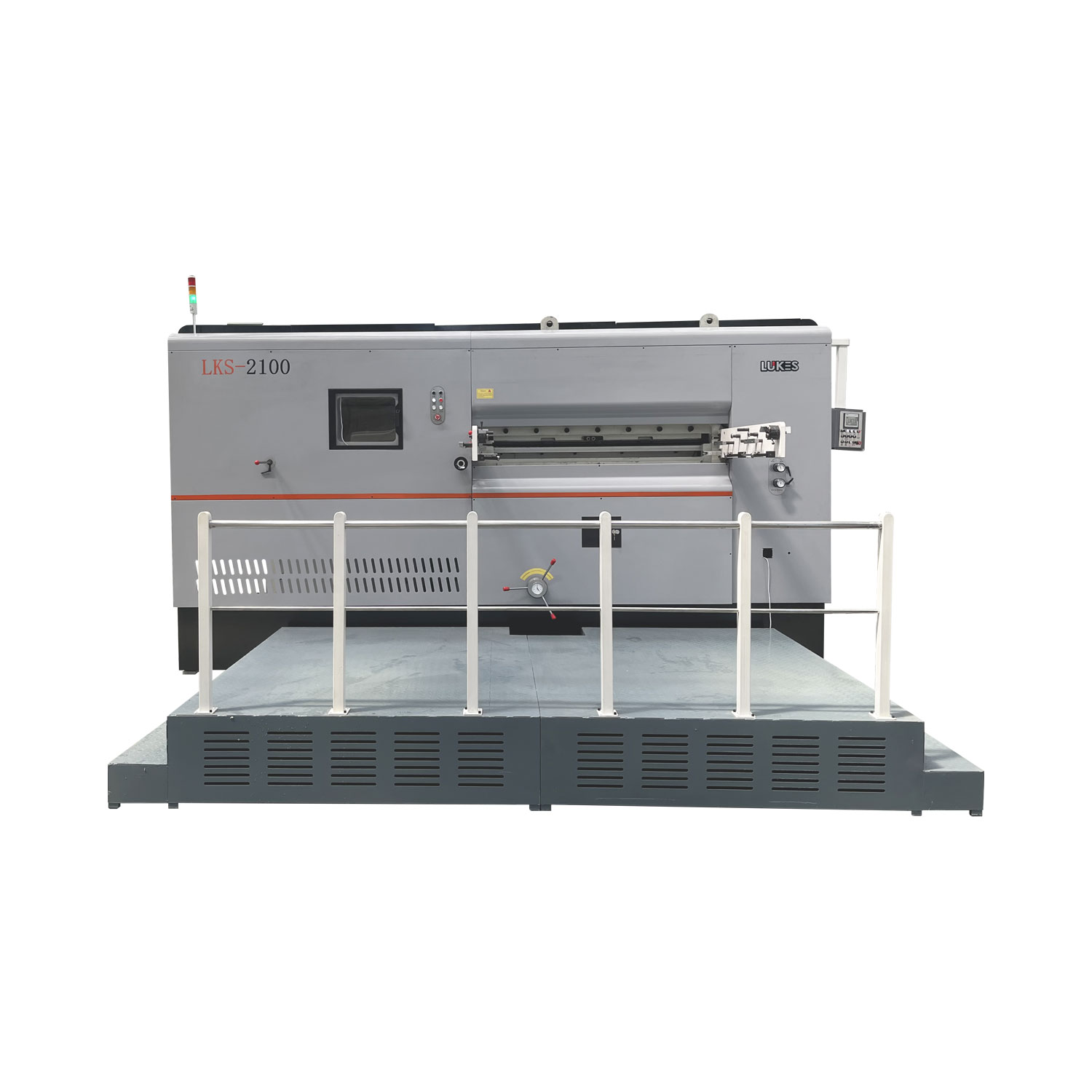

LKS2100 Semi Automatic Creasing Die Cutting Machine

Product Description

Model: LKS2100 Semi Automatic Creasing Die Cutting Machine

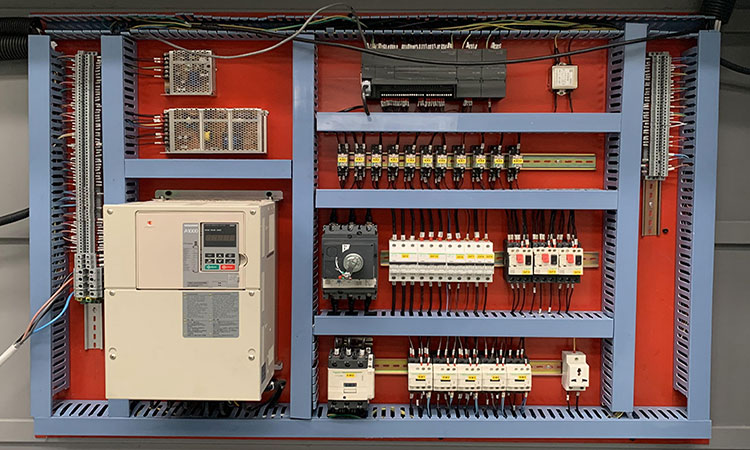

Characteristics:

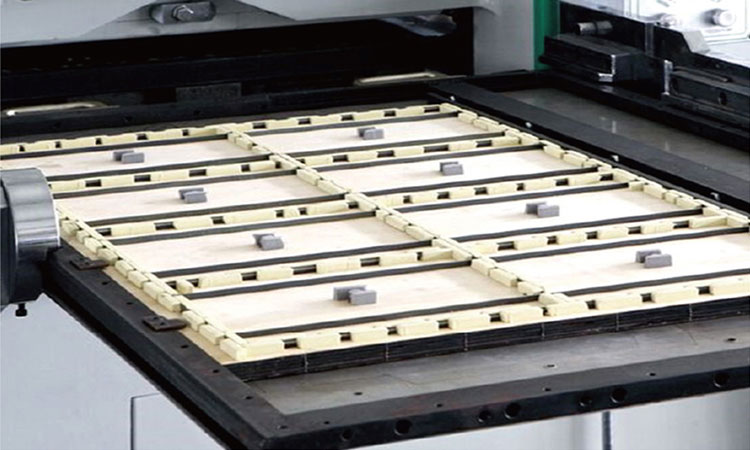

Stripping plate adopts central positioning system, automatic clamping.

Upper Stripping plate adopts electric control lifting device.

Semi stripping system can clean three sides and middle partautomatically with high efficiency.

Fully stripping system can clean four sides and middle partautomatically wiht high efficiency.

Description:

Semi automatic creasing die cutting machine is one of the best-selling products of Shandong Lukes Machinery. It can process cardboard and corrugated cardboard >250g, ≤9mm, suitable for die-cutting and creasing of cartons, cartons and other products. Especially good at die cutting Bend cardboard.