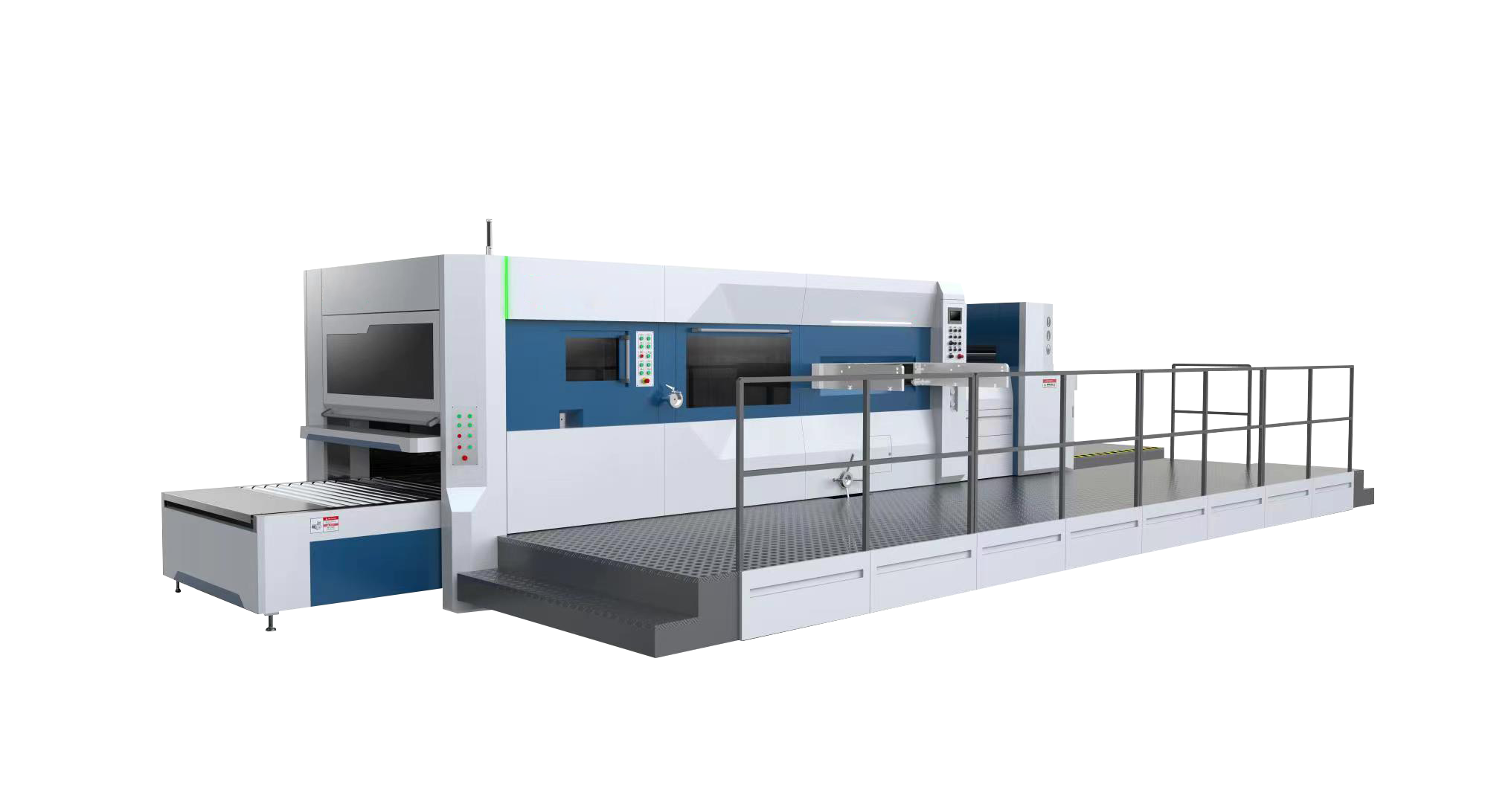

Semi Automatic Flat Bed Die Cutting Machine Advantages

We also all know that from the initial die cutting machine to the semi automatic flat bed die cutting machine, the current technology is very mature. The semi automatic die cutting machine adopts the principle of flat pressing, which is compact in structure, safe and reliable, and beautiful in appearance. Let me tell you about the advantages of the semi automatic die cutting machine.

The die cutting speed of the semi automatic flat bed die cutting machine is very fast, several times faster than the previous die cutting machine. Die cutting speed is the guarantee of the efficiency of the whole semi automatic die cutting machine. In addition to these, you also need to know that the design process has also evolved to increase the paper delivery size and height, allowing die cutting to produce more and different types of paperboard products. We all know that the traditional paper feeding method uses a conveyor belt, but the new model uses automatic paper suction technology, which can achieve the characteristics of fast and accurate paper suction. In particular, it can process cardboard and corrugated cardboard with a size greater than or equal to 250g and less than or equal to 9mm. It is suitable for the processing of cartons and cartons, especially good at die cutting of corrugated cardboard. Worm gear drive crankshaft connection, single point pull rod pressure regulation is the core of stable operation of the equipment. Of course, the feeder drive in the equipment is controlled by a servo motor, and the stroke of the suction nozzle is twice that of the ordinary suction nozzle, which is more suitable for the conveying of corrugated paper. The main drive of the semi automatic die cutting machine adopts large module worm gear drive, crankshaft, swing rod, connecting rod, bearing bush and its three dimensional cam indexing intermittent mechanism, which reduces the movement gap and keeps the machine running smoothly. The paper feeding part is equipped with a color video monitor, and the camera in the paper feeding part continuously monitors the paper feeding status, which provides convenience for the operator.

In addition, the semi automatic flat bed die cutting machine adopts PLC centralized control, which truly realizes the automation of paper feeding, die cutting and fault display. The main motor is controlled by a frequency converter, with stepless speed change and stable operation. The chain adopts imported chains, and its main drive bearings, frequency converters and various electrical switches are all European, American and Japanese products, with stable performance, accurate precision and long service life. The advantages of the semi automatic die cutting machine are fast production speed, large output, high safety factor, and no harm to people. With good precision, it can process all kinds of exquisite carton packaging. So what everyone needs to know is that this semi automatic die cutting machine adopts the current advanced technology and has high stability. interface. In addition, key components such as screws, bearings, chains, crankshafts, and turbines are mostly imported. Excellent performance, advanced technology, suitable for printing machines. Especially when the operator works on the template paper, the safety factor is higher and the hidden danger of operation is eliminated. Its typesetting is convenient and unlimited, saving time and greatly improving production efficiency.

After the introduction of the above content, we have also learned some advantages of the semi automatic die cutting machine. For detailed product information, welcome to contact us.