Working principle of automatic die cutting machine with stripping

Stripping is to separate the waste after die cutting from the main body of the package.

Due to its low production efficiency, manual stripping cannot guarantee the dimensional accuracy of complex box shapes, so it is suitable for products with small batches of die cutting, generally not higher than 10,000pcs.

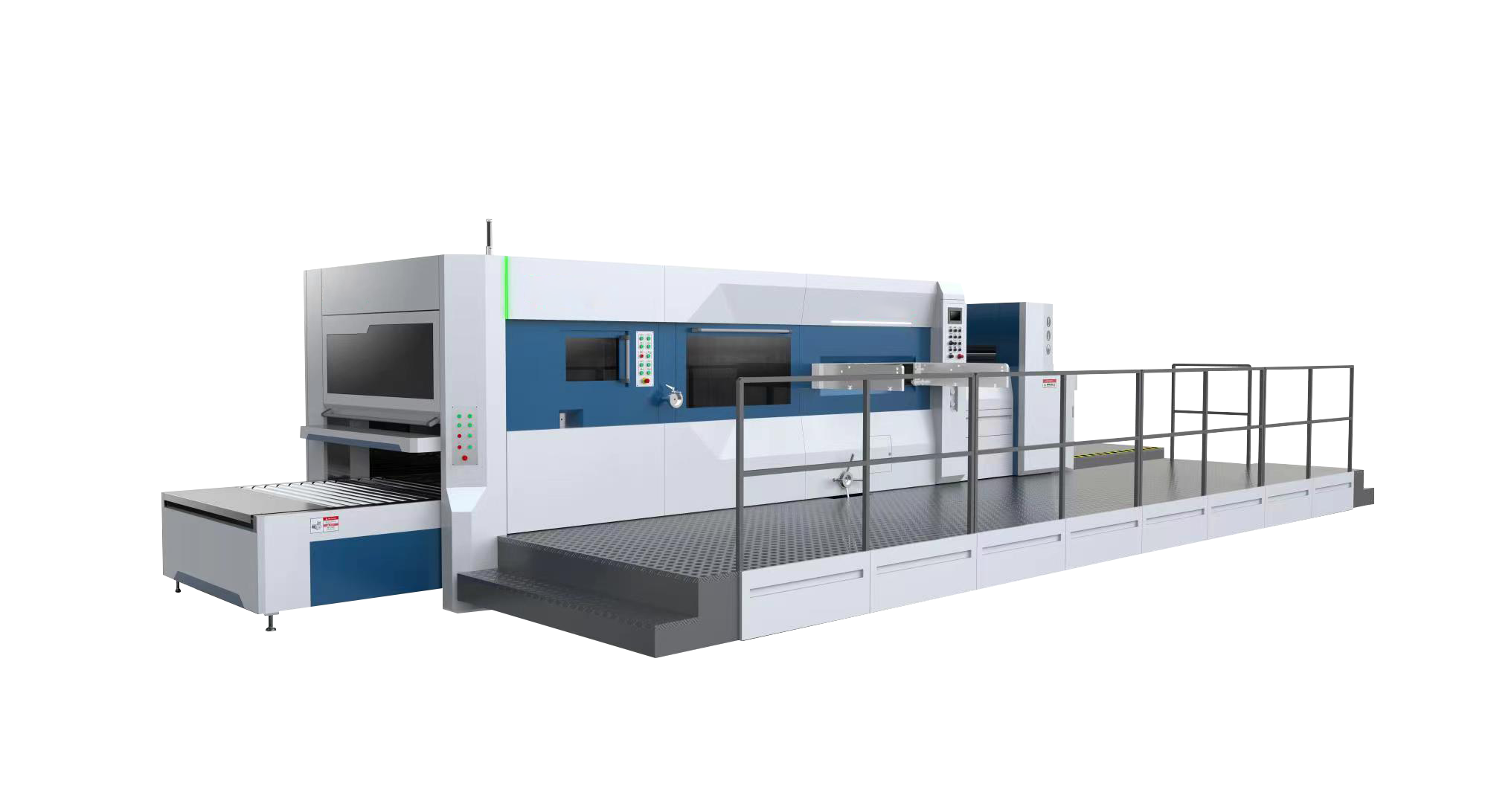

When the batch size is large, the automatic die cutting machine with stripping can be used for automatic stripping. The automatic die cutting machine with stripping has high production efficiency and can ensure the accuracy of the box size. However, the production of the stripping plate is complicated, and the price of the automatic die cutting machine with stripping expensive.

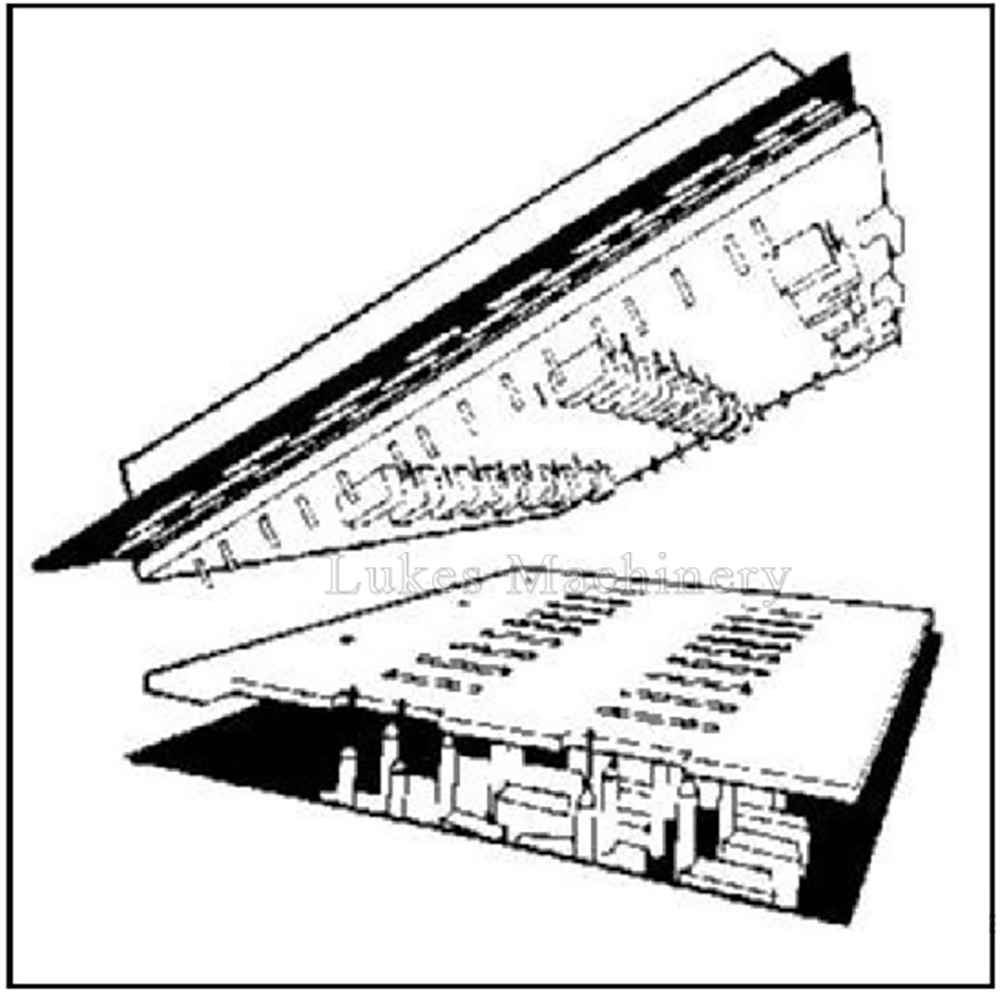

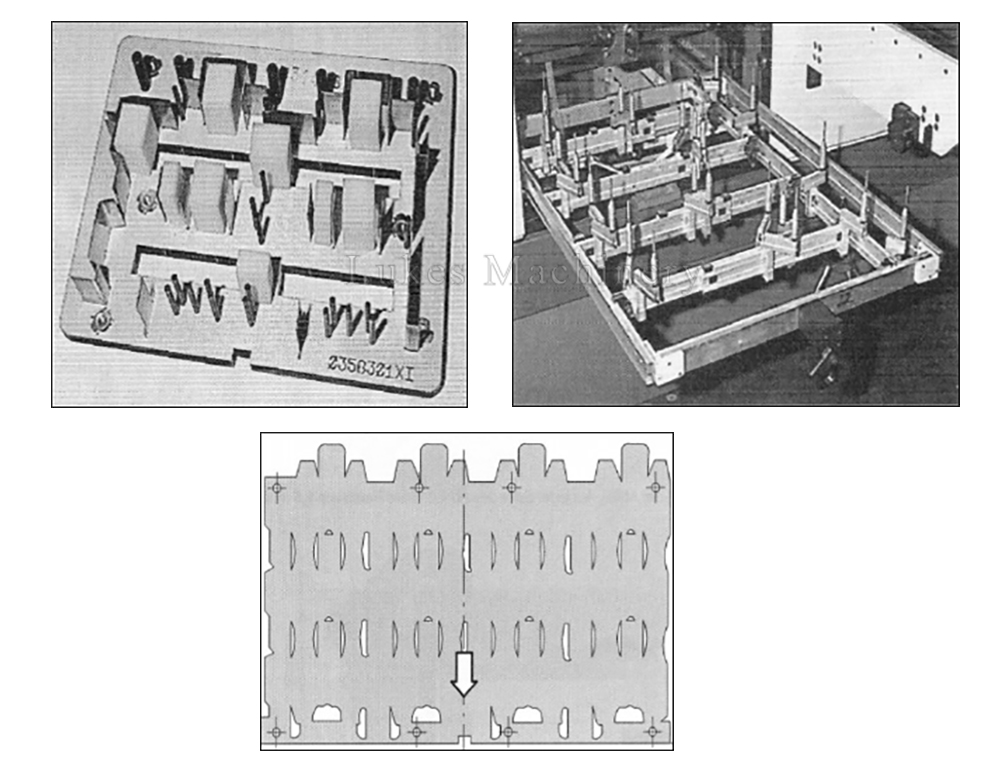

The automatic stripping device is composed of four parts, namely the middle stripping plate, the upper stripping plate, the lower stripping plate and the separation plate.

The middle stripping version is actually a female molded plywood, the upper stripping version is equipped with stripping steel bars, stripping pins and other devices, the lower stripping version is a stripping hanger with a lower thimble, and the separated version is the first strip in front of the outline of the die cutting version. The shape of the steel bar exactly matches the wooden bar.

The stripping device of the automatic die cutting machine with stripping is linked with the lower platen of the die-cutting device to remove the edge of waste paper other than the cardboard bitten by the teeth. The working principle of automatic stripping is: the upper stripping plate pin and the lower stripping plate thimble bite the paper and move downward, and the waste is knocked off with the assistance of the plywood of the female mold.