Working principle of hot stamping die cutting machine

Working principle of hot stamping die cutting machine

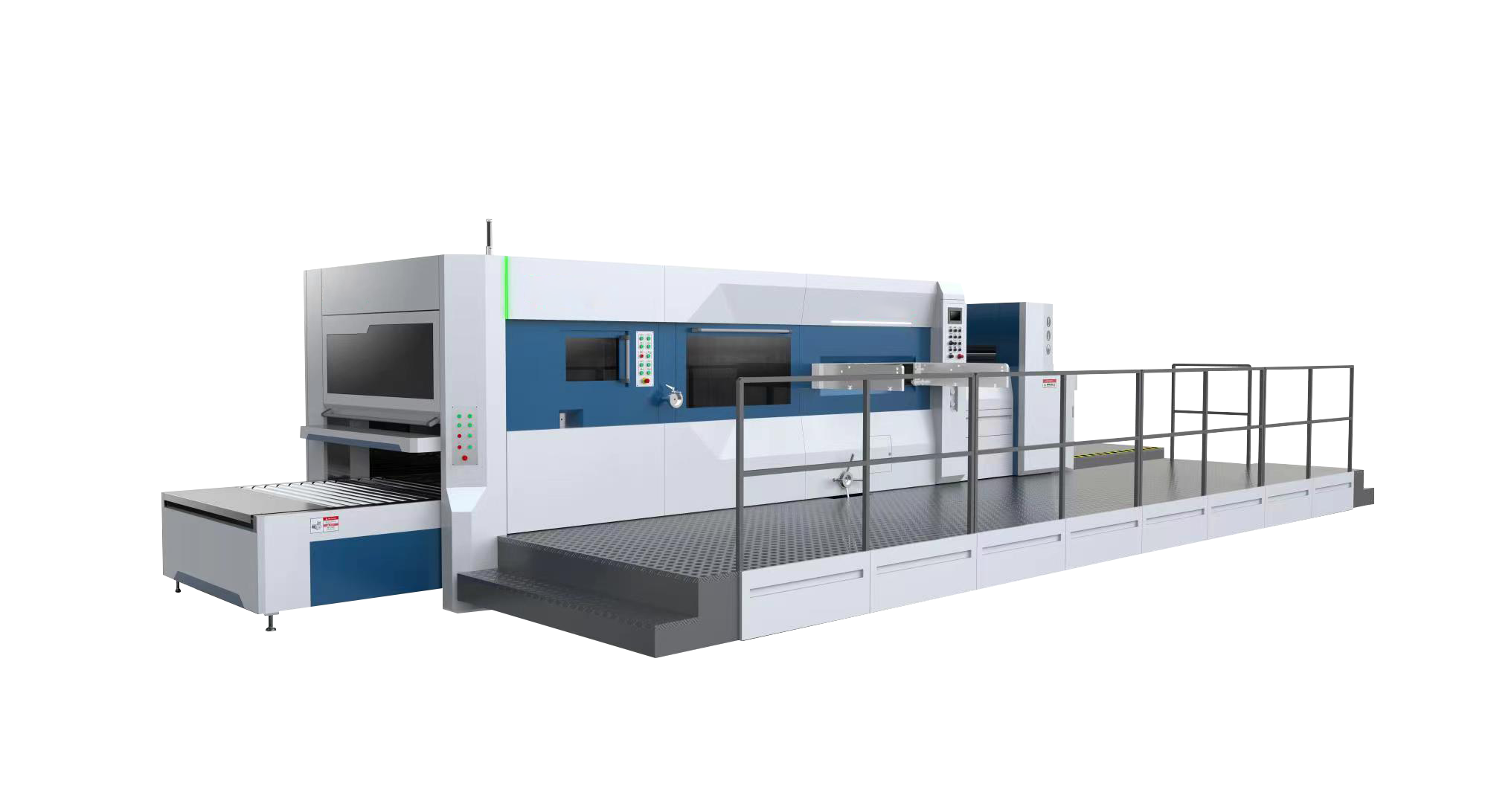

The working principle of the hot stamping die cutting machine is to attach the hot stamping foil or heat transfer foil to the surface of the hot pressing material, and then die cut to the desired shape.

Specifically, the working process of the hot stamping die cutting machine is to preheat the mold to a certain temperature, then place the hot stamping foil or heat transfer foil on the surface of the object to be hot stamped, and then press the mold on the hot stamping foil or heat On the surface of the transfer foil and the object, after a certain amount of time and pressure, the bronzing foil or heat transfer foil forms a layer of unique patterns or characters on the surface of the heat-pressed material.

The hot stamping die cutting machine uses high temperature and pressure to make the metal foil and color pigments on the hot stamping foil or hot stamping foil evenly pressed into the surface of the hot pressing material, thereby forming rich and varied decorations such as patterns, characters, and logos. Hot stamping die-cutting machine is widely used in the decoration of various printed matters such as gifts, cards, and paper packaging.